Punching line machine

Punching Line Machine for Lead-Acid Battery Grids. Automates high-speed production up to 35m/min with 220 punches/min, precise ±0.05mm pasting uniformity, accurate cutting, and integrated processing for superior efficiency, quality, and reliability in battery manufacturing.

- Information

- Video

Composition

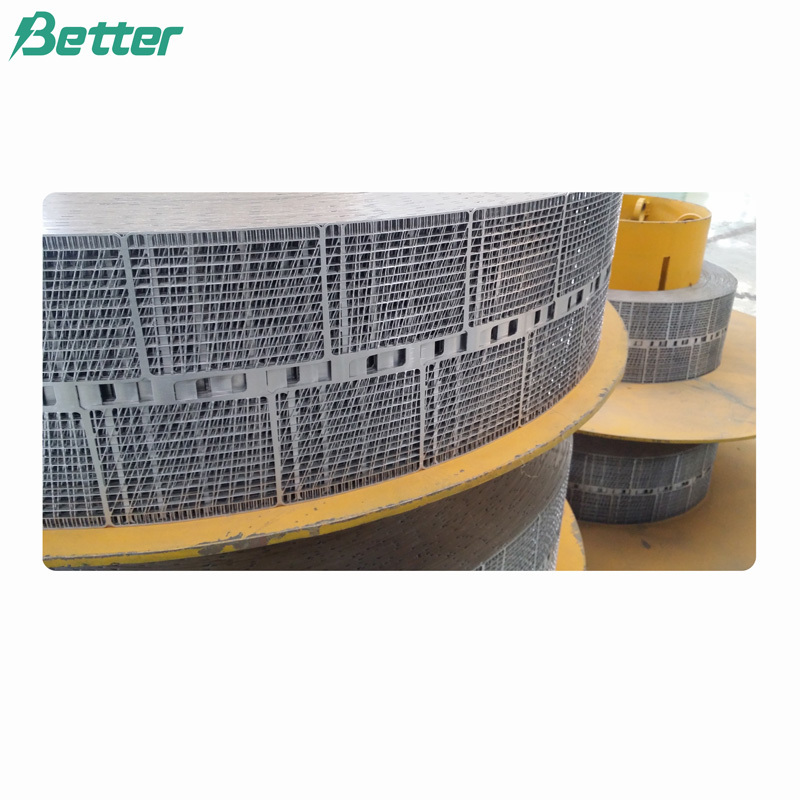

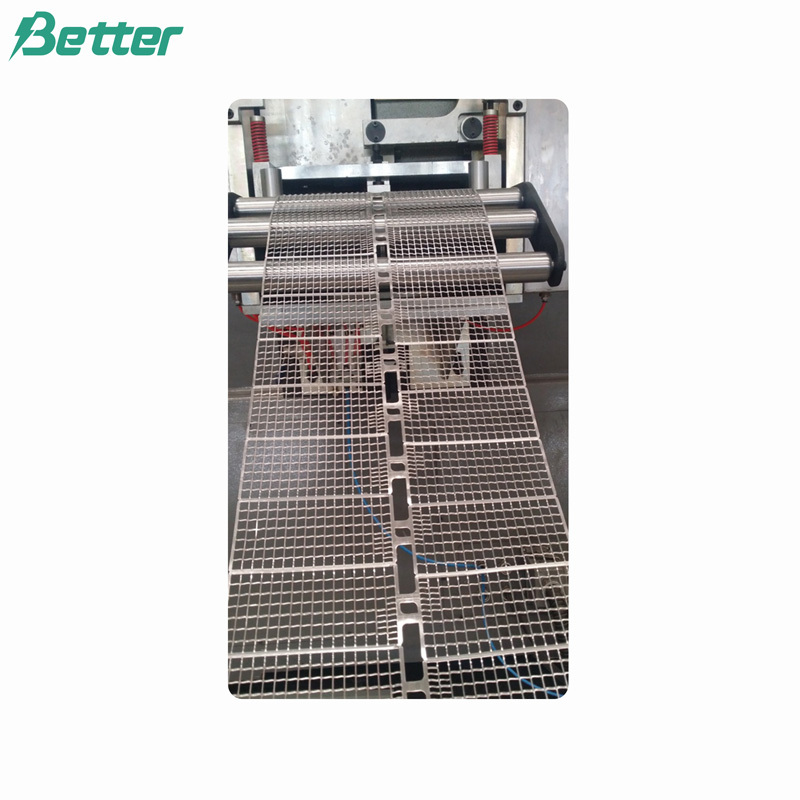

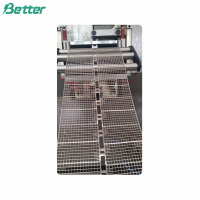

The punching line machine consists of 8 parts: Unwinding Machine, Lead Strip Welding Machine, Leveling Buffer Machine, Lead Strip Feeder, Press Machine, Punching mold, Horizontal Winding Machine and Electrical Control System.

Main Technical Parameters of Punching Line

| Item | Main Technical Parameter |

|---|---|

| Applicable Lead Strip | Lead strip width: 70~340mm, lead strip thickness: 0.7~1.2mm |

| Produced Grid Spec. | Max. continuous panel width: 320mm (grid height*2+lug height) ; Max. grid width: 150mm; |

| Production Capacity | Linear Speed: 28~35m/min (when grid width is 150mm); Punching time: 170~220 times/min |

| Total Power | Standard configuration: 42KW |

| Pneumatic System Pressure | 0.6MPa |

| Compressed Air Consumption | 3m³/h |

| Item | Technical Parameter |

|---|---|

| Max Pasting Size | Strip width: 80~330mm Plate thickness: 08~25mm |

| Pasting Speed | 20~3.5m/min (differ from grid design) |

| Pasting Uniformity | ±0.05mm |

| Installed Power of Pasting Machine | 14.5KW |

| Overall Dimension of Pasting Machine | 2385*1540*1880mm |

| Accuracy of Roll Cutter | Width accuracy: ±0.5mm, lug position tolerance: ±0.5mm |

| Transfer Speed of Drier | 3~28m/min (frequency control) |

| Temperature Control | 80~180℃ (control precision: ±2℃) |

| Heating Method of Drier (Steam Type) | Installed power: 82KW (auxiliary heating power is 72KW) Steam pressure: 0.3~0.4Mpa |

| Electrical Heating | Installed power: 163KW (electrical heating power is 158KW) |

| Natural Gas | Installed power: 15KW Natural gas consumption: 10~15m³/hr Natural gas pressure: 3.5~4mpa |

| Overall Dimension of Drier | L*W*H = 10500mm*1495mm*2392mm |