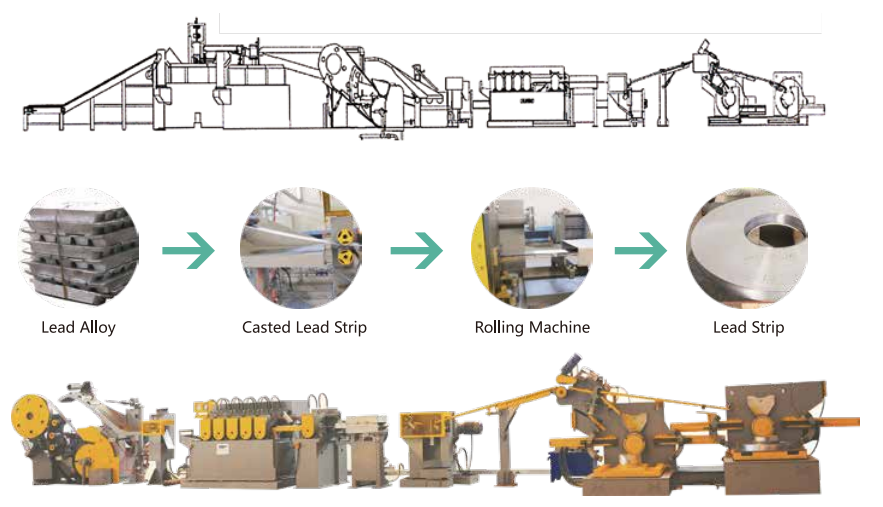

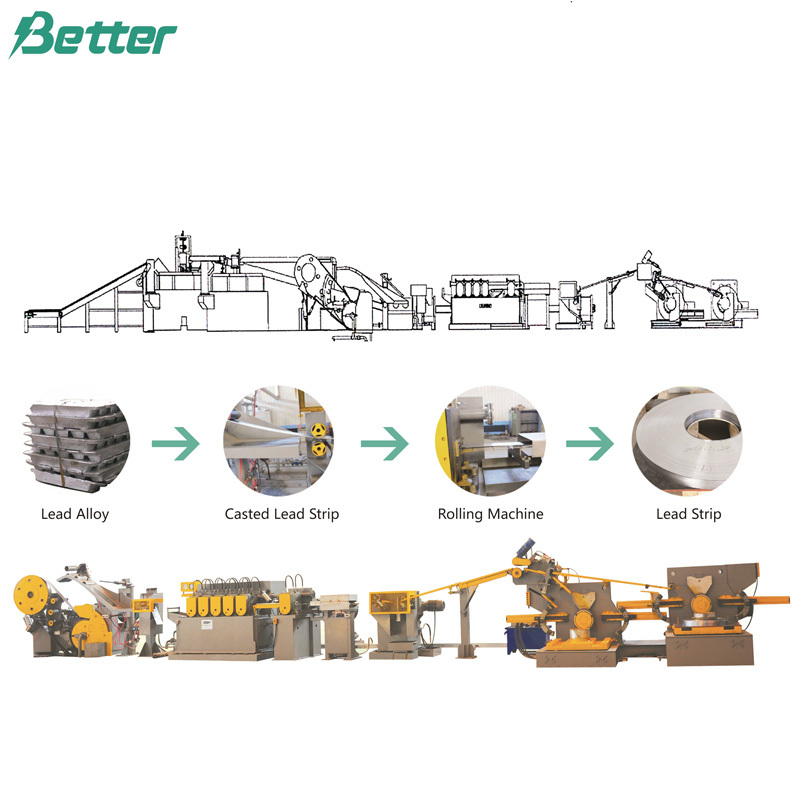

Lead Strip Production Line

This high-efficiency system integrates lead melting, continuous casting, precision rolling, and automatic recoiling. Featuring advanced PLC control and a scrap recovery system, it ensures uniform strip quality and high production speed while minimizing material waste and labor costs. Professional, reliable, and eco-friendly.

- Information

- Video

1. Lead Pot & Feeding System

It is composed of melting pot, holding pot, lead ingots and molten lead feeding system.

2. Strip Casting Machine

For continuous casting of raw lead strip of dimension 80mmx8mm.

3. Raw Strip Cutting Machine

It is used to cut the raw strip into small pieces and returns the strip back to melting pot if the downstream equipment fails or the initial few meters of strip needs to be scraped.

4. Rolling Machine 6+1

It is composed of rough rolling and finish rolling. Rough rolling has 6 pairs of rollers; finishing rolling has 1 pair rollers. The finish rolling is used to get final thickness of strip.

5. Strip Drying & Trimming Units

To clean the residual emulsion and dry the strip by blowing air. The trimming unit cuts the sides of the strip and trims it into the desired width. It can also cut the strip into small pieces so that the lead strip can be returned back to melting pot in case of failure in the subsequent processing.

6. Twin Recoiler

The finished lead strip can be coiled automatically. Two vertical coilers are transferred automatically.