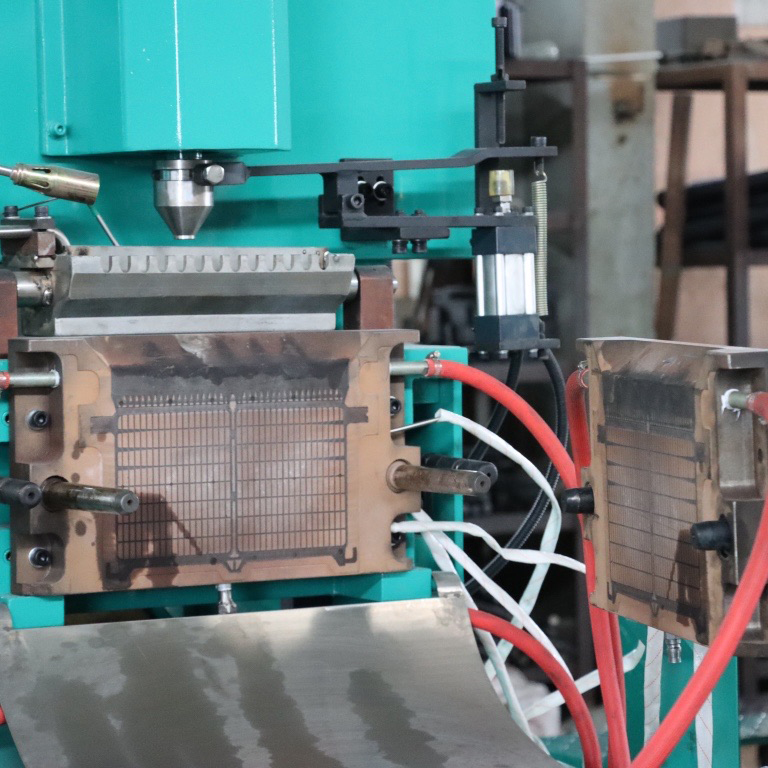

Lead battery Grid Casting Machine

The grid casting machine applies to the grid making for Lead acid battery, adopts Flat type cutting, which makes the grid without bending in the casting process.

- BETTER

- CHINA

- Information

- Video

This grid casting machine can be used for many different lead alloys, with high production capacity and good production quality. It adopts advanced technology and continuous promotion, which is energy-saving and easy to control and maintain.

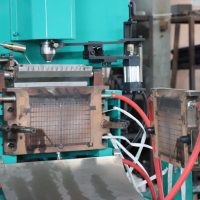

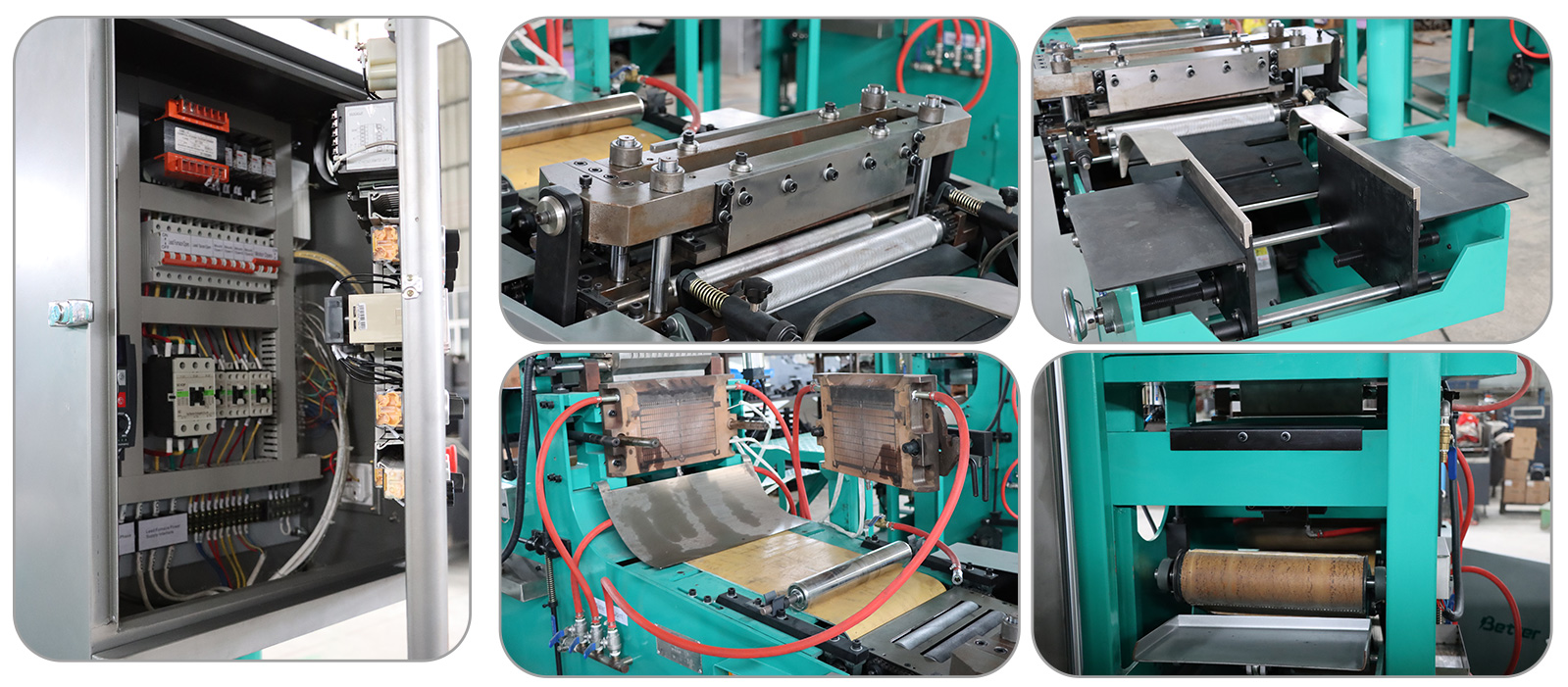

The main motor speed adopts imported frequency converter to realize continuously variable frequency. The opening and closing of the mold and the lead liquid supply are controlled by good-quality pneumatic components.

Lead supplying system takes quantitative lead control. Structure is simple. The lead valve spool can stand high temperature and be suitable for long-term use and easy to replace

The horizontal pull rod structure can ensure the machine move smoothly and reduce blur, so that reduce manual mold spraying to increase the production capacity.

Lead scrap recycling device can be optional, which can lower the labor strength.

Different heating methods are available, e.g. electrical heating, natural gas heating, LPG heating, etc.

Technical parameter

1. Production efficiency per unit: 8-17 Panels/min

2. Casting range: 370×(110-180)×(1.2-4.0)mm;

3. Grid mould: Manufactured according to the grid drawing of design provided by the user (Quotation does not include grid mould)

4. Total power:40kw (mold heating pipe:1 KW*4, lead scoop heating tube:3 KW. Main engine:1.5 KW, lead furnace:30 KW, lead valve heating:2 KW)

5. Dimension: 400*900*1900MM; Weight:2500KG

Functions

1. The main drive : the opening and closing of the mould, the quantitative supply of lead liquid is controlled by stable and reliable pneumatic components, and the others are mechanically driven, which is stable and reliable. The speed control of main engine adopts variable frequency speed governor, stepless speed regulation, wide adjustment range and simple speed regulation.

2. Lead supply system: lead supply system uses lead pump to drive and control lead liquid on and off, and with lead valve to supply lead, it is convenient to maintain the quantitative lead supply valve and reduce the downtime of equipment.

3. Lead spoon temperature control: the lead spoon thermocouple controls the opening and breaking of the electric heating tube, thus realizing the automatic control of the lead spoon temperature.

4. The Grid casting machine adopts flat cutter mechanism.The cutter system and the collecting system are transported in the same plane with the grid, so as to avoid the grid deformation caused by the impact in the slide plate, the tilting cutter and the collection process. The deformation of the grid during the casting process is significantly reduced, and the forming rate and production efficiency of the grid are greatly improved.