Battery Continuous Grid Casting Machine/Line

Battery Continuous Grid Casting Machine/Line

- BETTER

- China

- Information

- Video

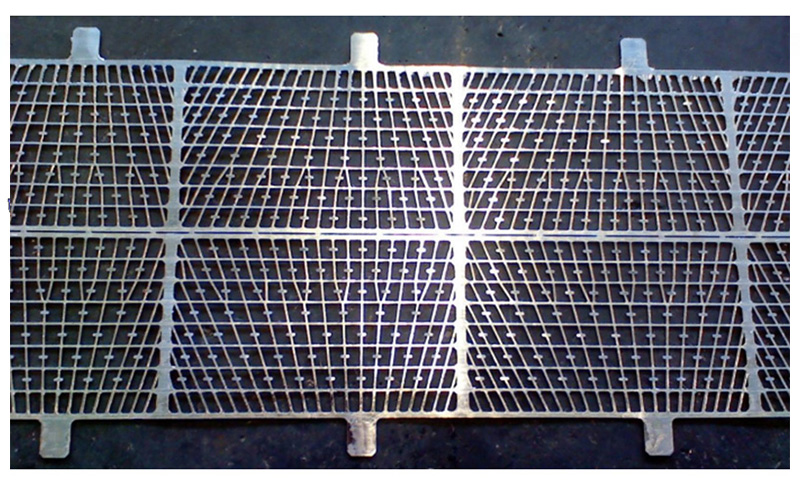

Grid Photo

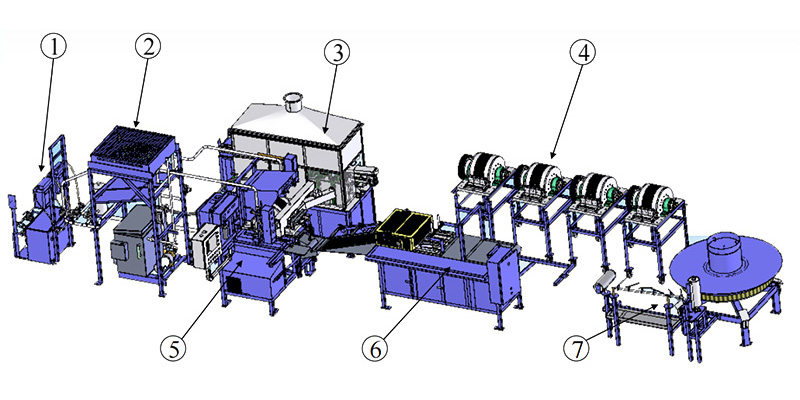

Components

① Cooling water and lubricant oil system

② Mold constant TMP. Cycling system

③ Lead furnace and automatic supply system

④ Casting mold

⑤ Main casting machine

⑥ Traction(Deburring) machine

⑦Winding machine

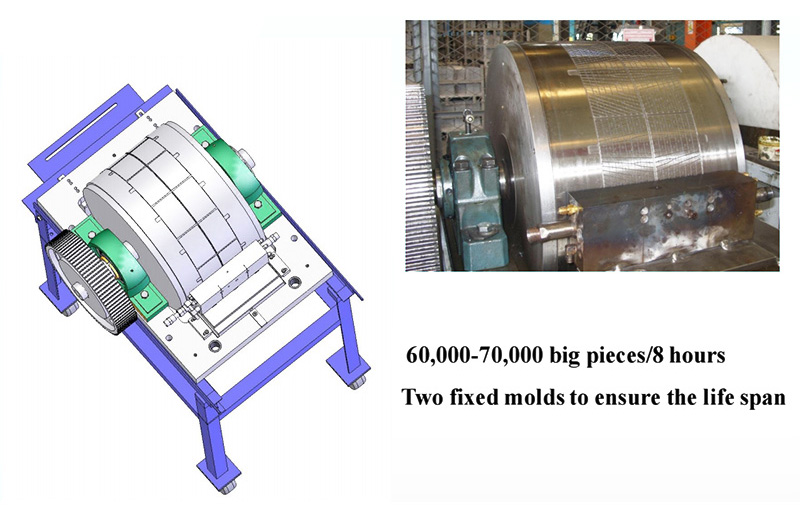

Casting Mold

60,000-70,000 big pieces

8 hours Two fixed molds to ensure the life span

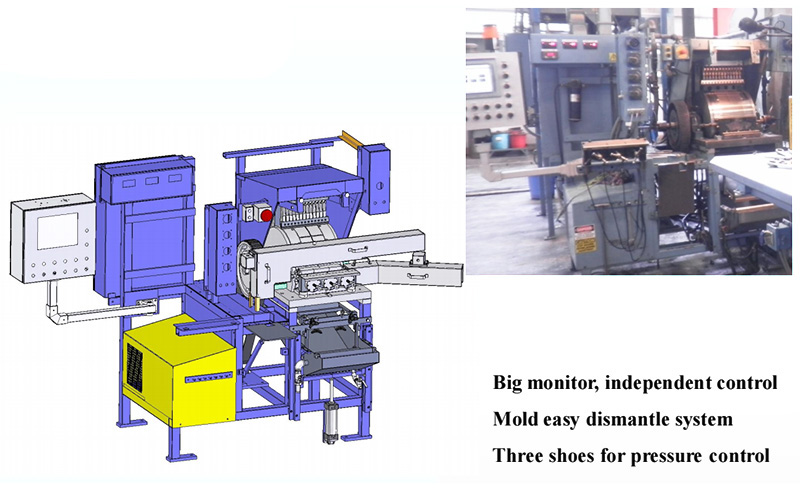

Main Casting Machine

Big monitor, independent control

Mold easy dismantle system

Three shoes for pressure control

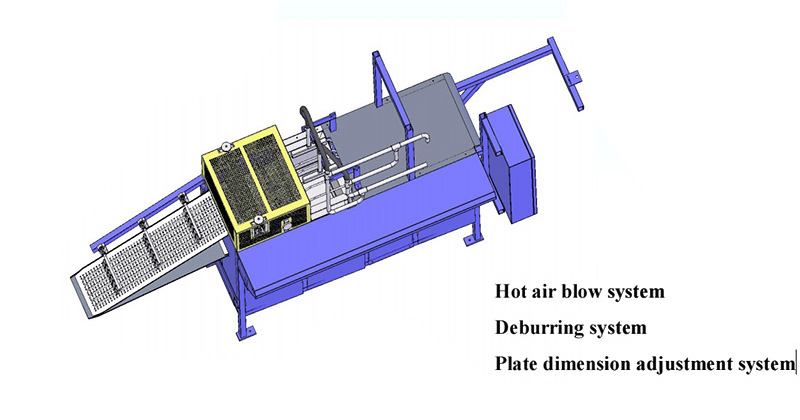

Traction(Deburring)Machine

Hot air blow system

Deburring system

Plate dimension adjustment system

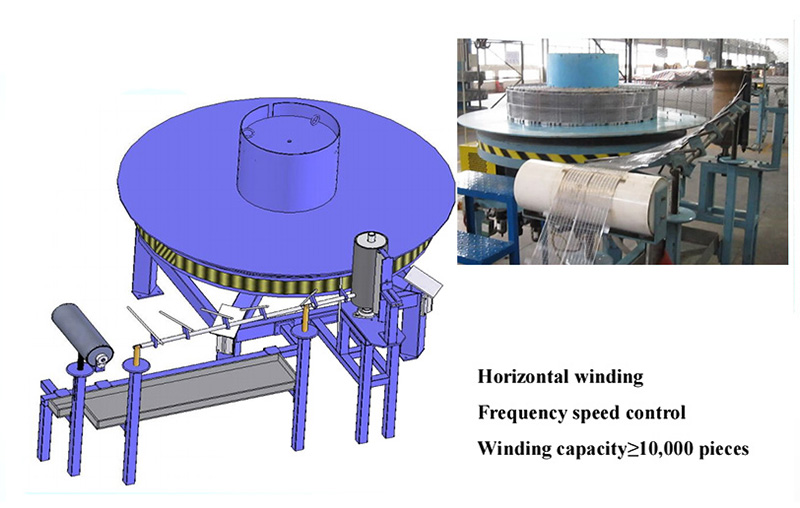

Winding Machine

Horizontal winding

Frequency speed control

Winding capacity≥10,000 pieces

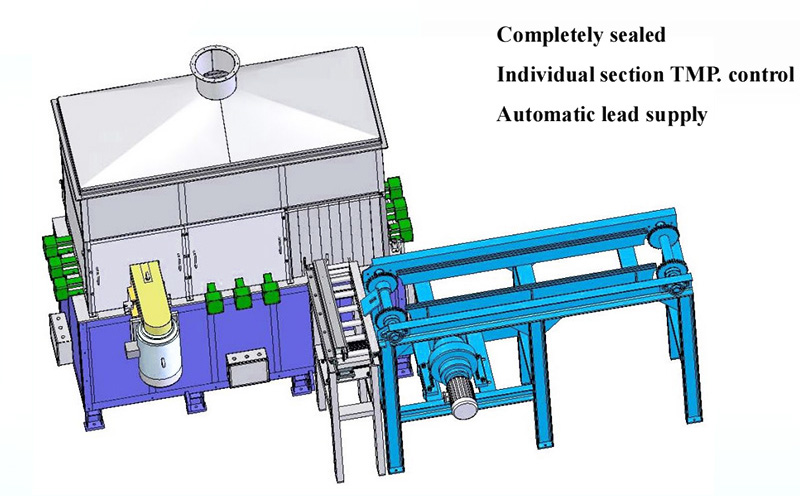

Lead Furnace

Completely sealed

Individual section TMP. control

Automatic lead supply

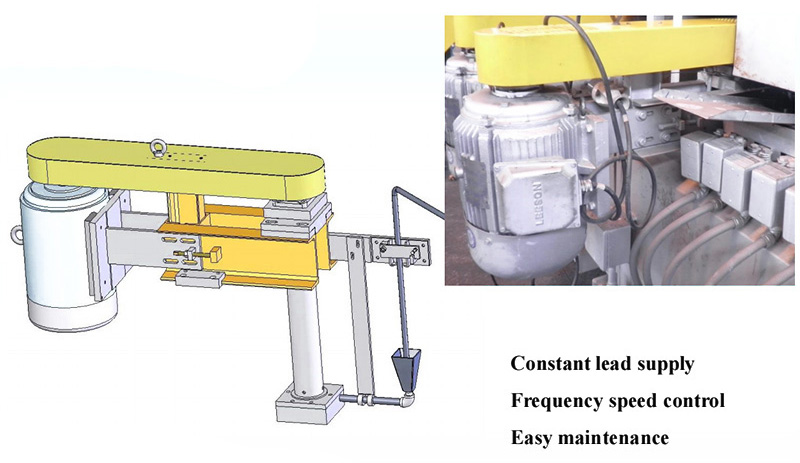

Lead Pump

Constant lead supply

Frequency speed control

Easy maintenance

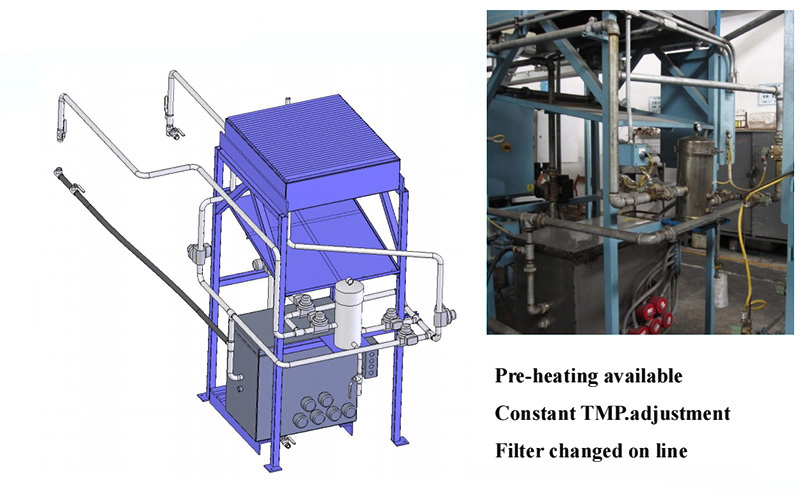

Mold Constant TMP. Cycling system

Pre-heating available

Constant TMP.adjustment

Filter changed on line

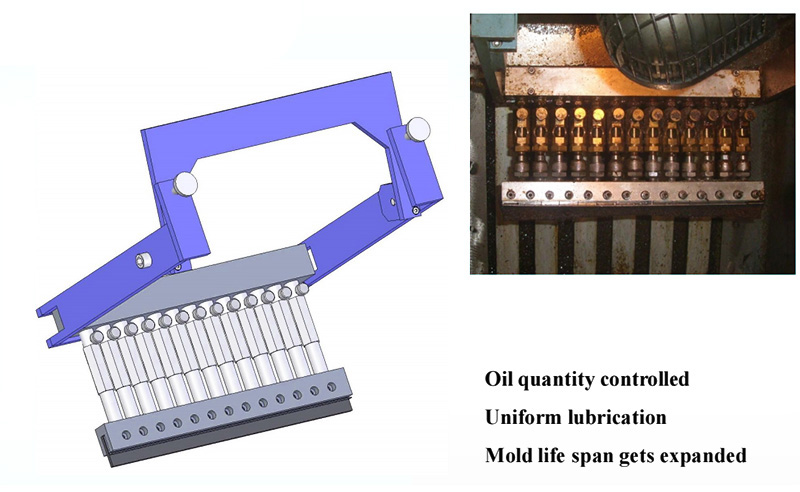

Lubricant oil system

Oil quantity controlled

Uniform lubrication

Mold life span gets expanded

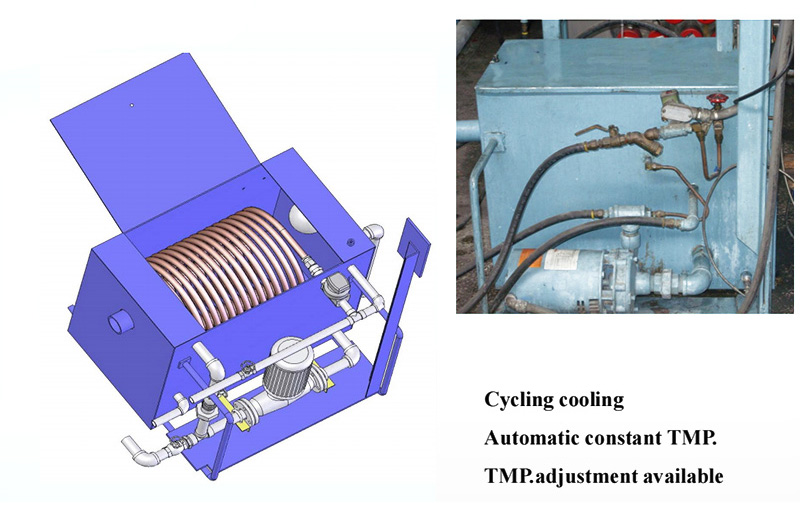

Cooling water system

Cycling cooling

Automatic constant TMP.

TMP.adjustment available

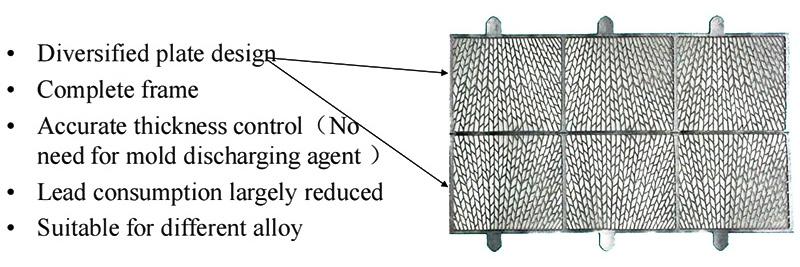

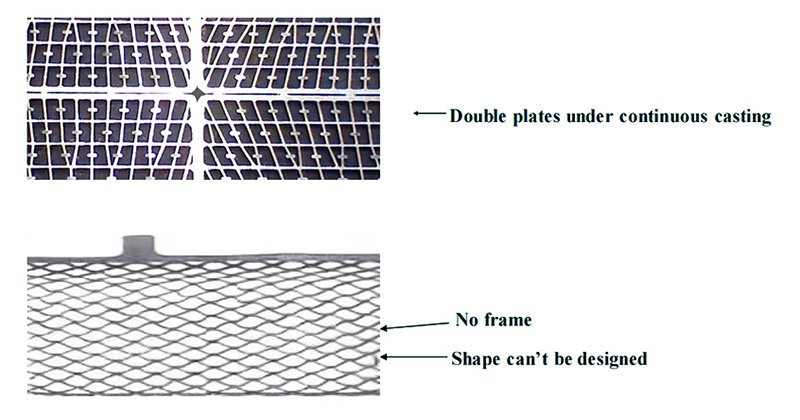

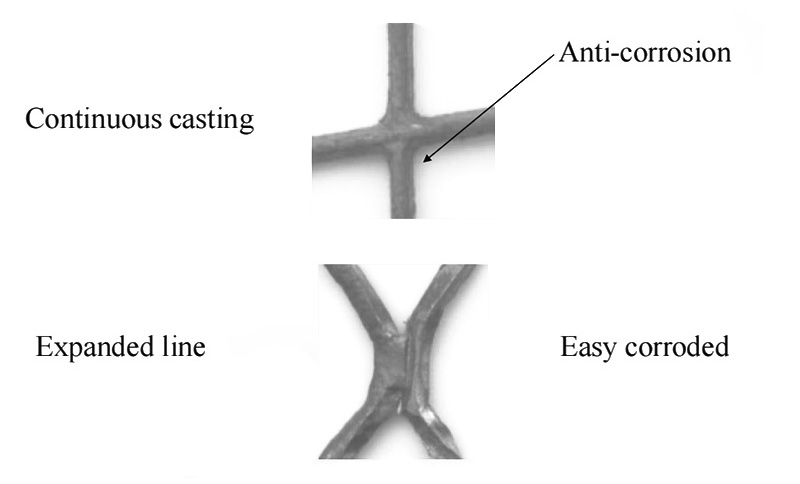

Plate features under continuous casting

You can note the difference!!

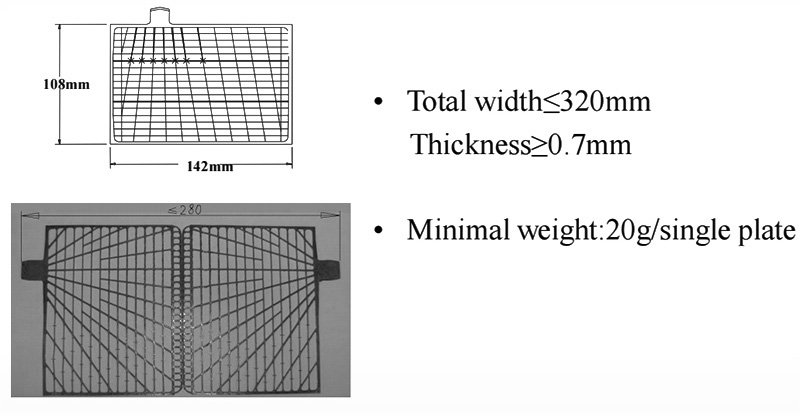

Plate design dimension

Plate design dimension

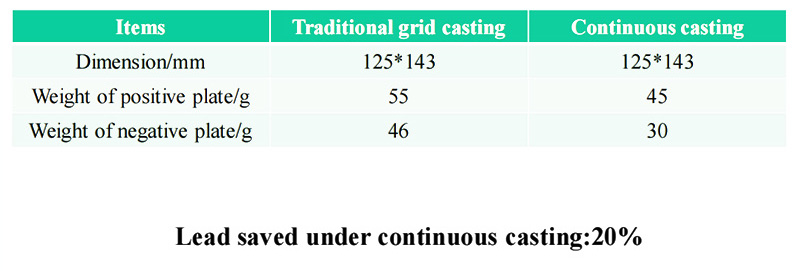

Lead consumption compared with traditional casting machine

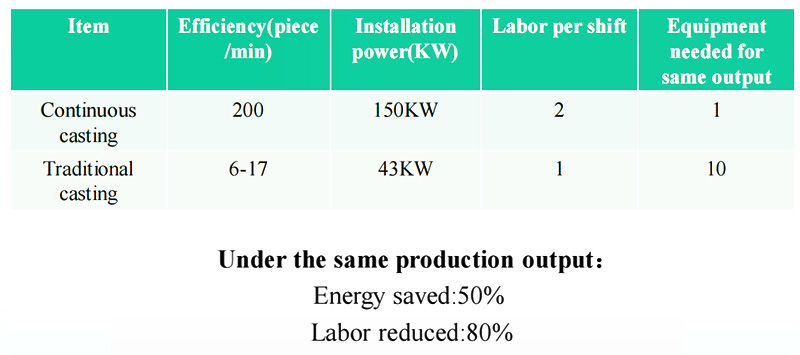

Energy&Labor consumption compared with traditional casting