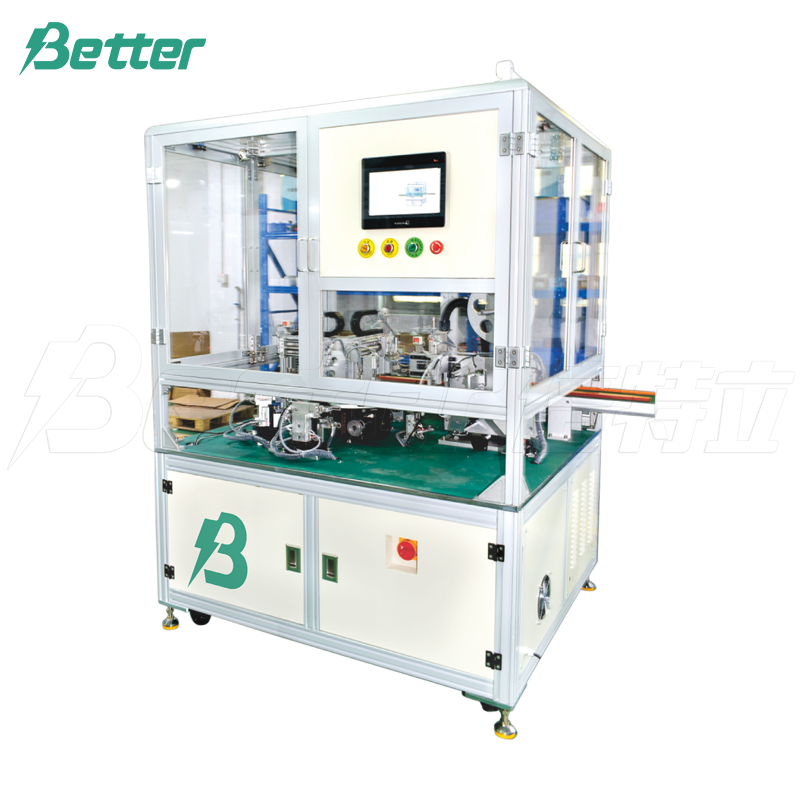

Cell Lateral-Side Taping Machine

Side gluing machine is an automatic equipment for polymer battery processing, which is used to paste insulation glue on both sides of soft pack batteries, and can complete three types of L, U and C gluing Craft.

- Information

Introduction of use

Designed for insulating tape application on lateral sides of batteries, capable of performing three tape patterns: L-shape, U-shape, and C-shape.

Technological process

Cell feeding & positioning

Auto tape feeding

Auto tape application

Tape rolling

Auto discharge

Technical Parameter

Battery dimensions:L:40-120 W:35-100 T:3-10

width range:8mm-20mm L/U-shape

Tape core inner diameter:∅76

Taping accuracy:±0.25

Tape thickness:≥0.03

Equipment operating rate:≥98%

Yield rate:≥99%

Air source pressure:0.5MPa

Total power:2KW

Ambient temp.:0-50℃

Power supply voltage:220V 50Hz

Production capacity:≥1000PCS/H

Machine dimensions LWH (mm):1600*1200*1900mm

Functional characteristics

High compatibility----adapt to three types of tapes (L/U/C-shape)

Tape application & tape rolling systems, easy to change cell model

Unique tape rolling ensures neat taping without bubbles and wrinkles

Simultaneous tape feeding and application on both lateral sides, improving efficiency

Full-range vacuum monitoring

Anti-static belt protects batteries

User-friendly intuitive operation