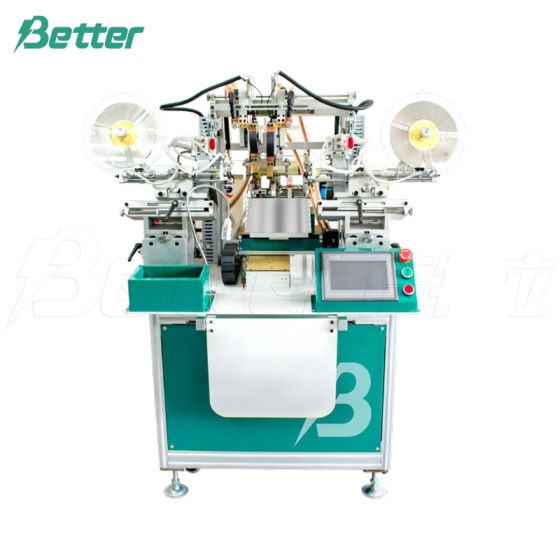

Laser Welding Machine

Laser Welding Machine for polymer batteries. Automates tab flattening, BMS feeding, and precise welding at ≥1000pcs/h with ±0.1mm accuracy, ≥99% yield, and ≥98% uptime for safe, robust, and efficient lithium battery assembly.

- Information

Introduction of use

Features auto tab flattening, auto BMS feeding, BMS detection & positioning functions. It enables safe, precise, and robust welding between battery cells and BMS.

Technological process

Cell feeding & positioning

Tab flattening

Manual BMS placing on tray

Robot hand BMS picking from tray

BMS detection & positioning

Laser welding of BMS & tab

Auto discharge

Technical parameter

Battery dimensions:L:40-120 W:35-90 T:3-10

Laser welding accuracy:±0.1

Tab length:4-20

Tab distance:10-70

Equipment operating rate:≥98%

Yield rate:≥99%

Air source pressure:0.5MPa

Total power:2KW

Ambient temp.:0-50℃

Power supply voltage:220V 50Hz

Production capacity:≥1000PCS/H

Machine dimensions LWH (mm):1200*1200*1900mm

Functional characteristics

Cell feeding & positioning

Tab flattening

BMS dual-station auto feeding

Easy feeding with robot hand; precise positioning according to the coordinates

Anti-static belt protects batteries

User-friendly intuitive operation