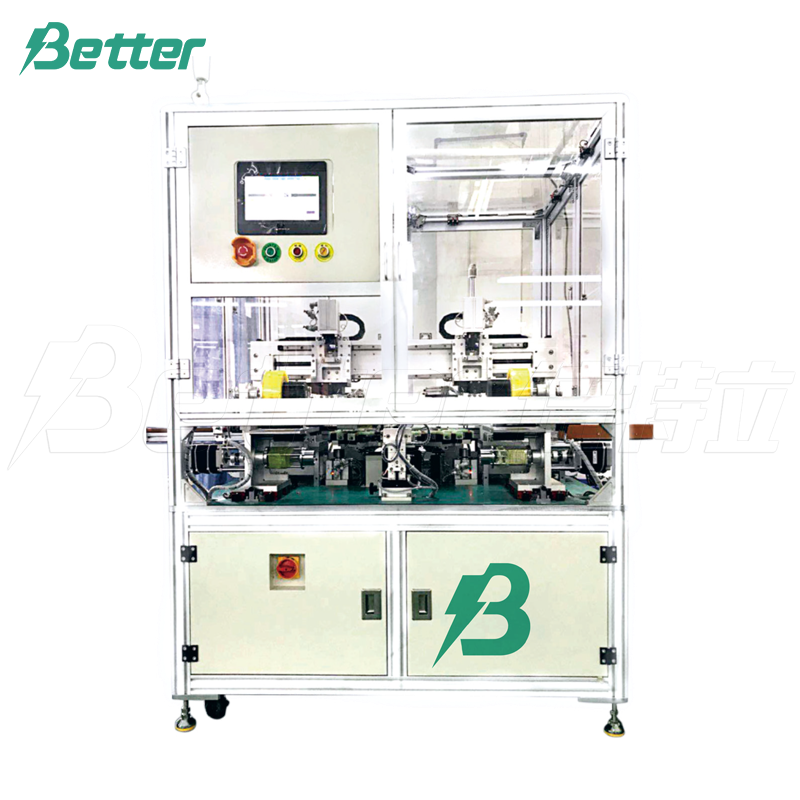

Double-sided pad printing machine

The double-sided pad printer is an automated equipment for polymer battery processing. It is used for pad printing on the front and back of polymer cells or batteries. It has an automatic pad head cleaning auxiliary function. It is suitable for fast-drying ink pad printing.

- Information

Introduction of use

The double-sided pad printer is an automated equipment for polymer battery processing. It is used for pad printing on the front and back of polymer cells or batteries. It has an automatic pad head cleaning auxiliary function. It is suitable for fast-drying ink pad printing.

Technological process

Cell feeding

Positioning

Front-side pad printing

Drying

Cell flipping

Back-side pad printing

Discharge

Technical parameter

Battery dimensions:L:40-120 W:35-90 T:3-8

Equipment operating rate:≥98%

Yield rate:≥99%

Air source pressure:0.5MPa

Total power:2KW

Ambient temp.:0-50℃

Power supply voltage:220V 50Hz

Production capacity:≥1000PCS/H

Machine dimensions LWH (mm):1400*1200*1900mm

Functional characteristics

1.Fully automatic operation, closed pad printing environment, less ink usage, less odor, and exhaust holes are made on the top of the machine according to customer requirements. It has an automatic pad printing rubber head cleaning function, and the pad head cleaning frequency can be set, without manual cleaning.

2.One machine completes the front and back text pad printing.

3.The text is printed clearly, and compared with silk screen printing, it is more efficient and less costly.

4.All-round vacuum monitoring

5.Selected anti-static belts, no damage to batteries

6.Humanized program design, simple operation, easy to learn and understand