- Home

- >

News

A lead acid battery grid is the structural backbone that holds the active material inside every lead acid battery. Think of it as a metal frame that supports the paste responsible for storing and releasing energy. Without a well-made grid, the battery simply wouldn't function reliably.

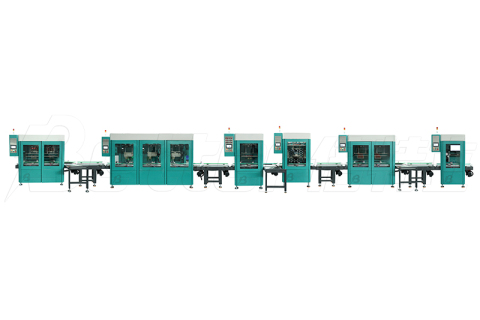

Struggling to keep your battery production line efficient and consistent? The Lead Acid Battery Double Sides Pasting Machine from Better Technology Group Limited might just what you need.

Recently, Wellpack New Energy Technology (referred to as Wellpack), a domestic subsidiary of Better Technology Group Limited (referred to as Better Tech Group), held its MES project kickoff meeting under the theme "Powering Progress Through Digital Intelligence" at the group's factory. Senior leadership, R&D, technical teams, and project partners attended the meeting.

Sealed lead-acid (SLA) batteries are widely used in various applications, including backup power systems, electric vehicles, and industrial machinery.

Before initiating a battery production facility, it is essential to understand the various stages of lead acid battery manufacturing. The core processes include:

Setting up a battery manufacturing plant requires careful planning, the right equipment, and efficient production processes.

Lead-acid batteries have been the go-to solution for many energy storage needs for more than a century, thanks to their reliability, cost-effectiveness, and long-lasting performance.

Lead-acid batteries have been in use for more than a century and continue to be an essential technology in various applications, from powering vehicles to providing backup energy storage.

Battery manufacturing plays a pivotal role in the global economy, as batteries power everything from household electronics to electric vehicles and renewable energy systems.

Traditional lead-acid batteries, with their heavy weight and short lifespan, struggle to meet the demands of modern motorcycle rental services.