- Home

- >

News

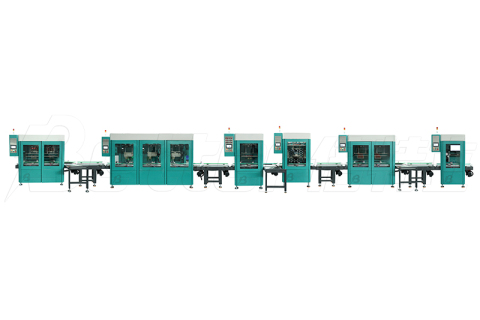

Struggling to keep your battery production line efficient and consistent? The Lead Acid Battery Double Sides Pasting Machine from Better Technology Group Limited might just what you need.

At Better Technology Group Limited, we've designed a turnkey solutions for battery manufacturing that supports businesses crafting lead-acid batteries for motorcycles, vehicles, or industrial equipment.

Zambia, July 24, Airumi New Energy, an overseas subsidiary of Better Technology Group Limited (hereinafter referred to as Better Tech Group), held a charity donation event in Zambia, providing footballs to the country’s Ministry of Youth Sport and Arts. This initiative aims to support sports programs in under-resourced schools and communities, offering tangible assistance to local youth development and also adding a heartwarming chapter to the China-Zambia friendship.

On June 25, Better Technology Group Limited (referred to as Better Tech Group) organized a fire safety training and drill activity at its factory. The event featured expert guidance from the local fire brigade, with participation from all factory staff and department representatives.

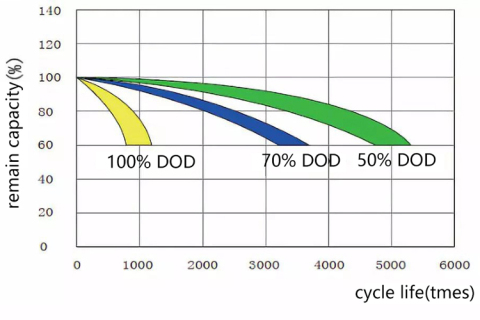

Understanding core technical parameters is critical when selecting lead-acid batteries (especially gel or lead-carbon types). This guide breaks down rated voltage, max charge/discharge currents, depth of discharge (DOD), cycle life, and power calculations to help you optimize battery lifespan and system design.

Recently, Wellpack New Energy Technology (referred to as Wellpack), a domestic subsidiary of Better Technology Group Limited (referred to as Better Tech Group), held its MES project kickoff meeting under the theme "Powering Progress Through Digital Intelligence" at the group's factory. Senior leadership, R&D, technical teams, and project partners attended the meeting.

Sealed lead-acid (SLA) batteries are widely used in various applications, including backup power systems, electric vehicles, and industrial machinery.

Before initiating a battery production facility, it is essential to understand the various stages of lead acid battery manufacturing. The core processes include:

Setting up a battery manufacturing plant requires careful planning, the right equipment, and efficient production processes.

Lead-acid batteries have been the go-to solution for many energy storage needs for more than a century, thanks to their reliability, cost-effectiveness, and long-lasting performance.