- Home

- >

- News

- >

- Product Information

- >

News

The plate charging stage is critical for battery production. Our Plate Charging Machine, crafted by Better Technology Group, transforms this step into something smooth and dependable.

Looking to streamline your lead-acid battery production? The Automatic Acid Filling Machine from Better Technology Group Limited is your answer.

Our Communication Battery 48V100Ah from Better Tech Group is built to keep your systems humming, no matter the challenge.

Imagine your home glowing at night, appliances running smoothly, and energy bills staying low. That's the beauty of a household energy storage battery system from Better Tech Group.

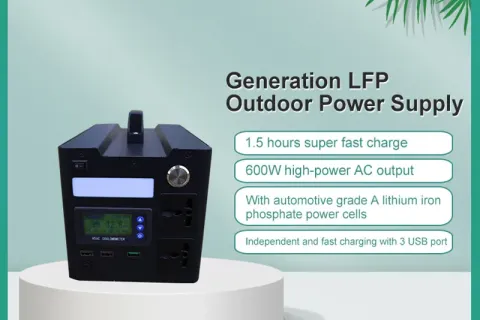

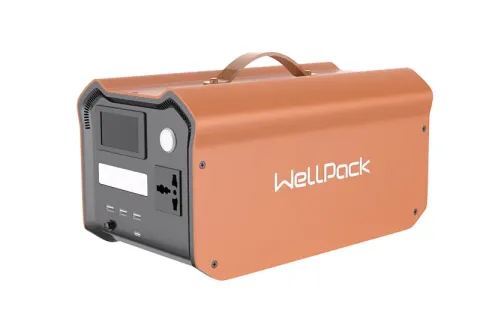

Looking for a dependable Portable Power Station that's easy to carry yet powerful enough for work and play? The WPP1200-01 from Better Tech Group brings LiFePO4 chemistry, fast charging, and a pure sine wave inverter together in a compact package.

if you're in the battery manufacturing game, you know how critical precision and efficiency are. That's where our separator enveloping & stacking machine comes in

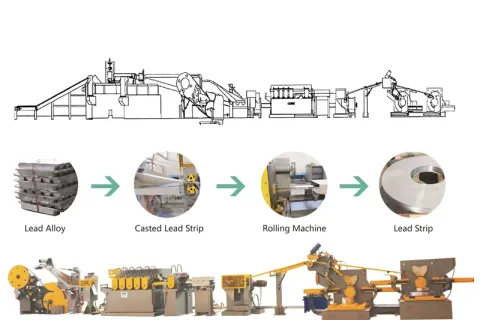

our Lead Strip Production Line comes is designed to streamline your production process with top-notch reliability

Our solar panel portable power station shines here with its LiFePO4 or NMC battery options, packing a solid 460Wh capacity that handles everything from charging drones to powering small medical setups.

The sun dips low, and you need reliable power to charge up laptops, run some lights, or even power a small drone for aerial surveys. That's where the portable power station for camping from Better Tech Group steps in

Looking to level up your lead-acid battery manufacturing? Let's chat about the Battery Plate Brushing Machine from Better Technology Group Limited.

Looking to streamline your battery manufacturing process? Let's talk about the Battery Plate Cutting Machine from Better Technology Group Limited.