Lead Smoke Purification System

Lead Smoke Purification System applies to purifying the Lead smoke coming from the Grid casting machine and COS machine.

- BETTER

- CHINA

- Information

Lead Smoke Purification System

Equipment Name

HKE Lead Smoke Scrubber & VST Wet Scrubber

Treatment Capacity

There are 12pcs grid casting machines, we design one set lead smoke purification system; the designed capacity is 20,000m3/h.

Equipment Composition

The whole system consists of suction hood, ventilation ducting, HKE lead fume scrubber, VST wet scrubber, blower, chimney, and electrical cabinet, etc.

Set up suction hood overhead the pollution source, the suction hood will generate strong air attraction with force of the blower; the lead fume will be sucked into the ventilation ducting.

Function of the suction hood is to capture the lead fume and generate a strong negative pressure area, forcing the lead fume moving into the suction hood. Function of the ventilation system is to ensure the ventilation of air flow. Function of the blower: the blower is just like the heart of the system, the power source of circulation air flow; the blower is placed behind the scrubber, which will protect the impeller from impact of high-speed and disordered dust particles, improving the service life and reducing the backpressure, ensuring the normal long-term operation. The lead fume will integrate into the scrubber, and the treated air will be discharged from the chimney via the blower. Each suction hood is equipped with independent air valve for adjusting the air flow; if there is no need to open at the same time, the operator can close it, making the negative pressure of the running suction hood much stronger, more beneficial to the lead fume gathering.

Working Principle

1. Process Flow

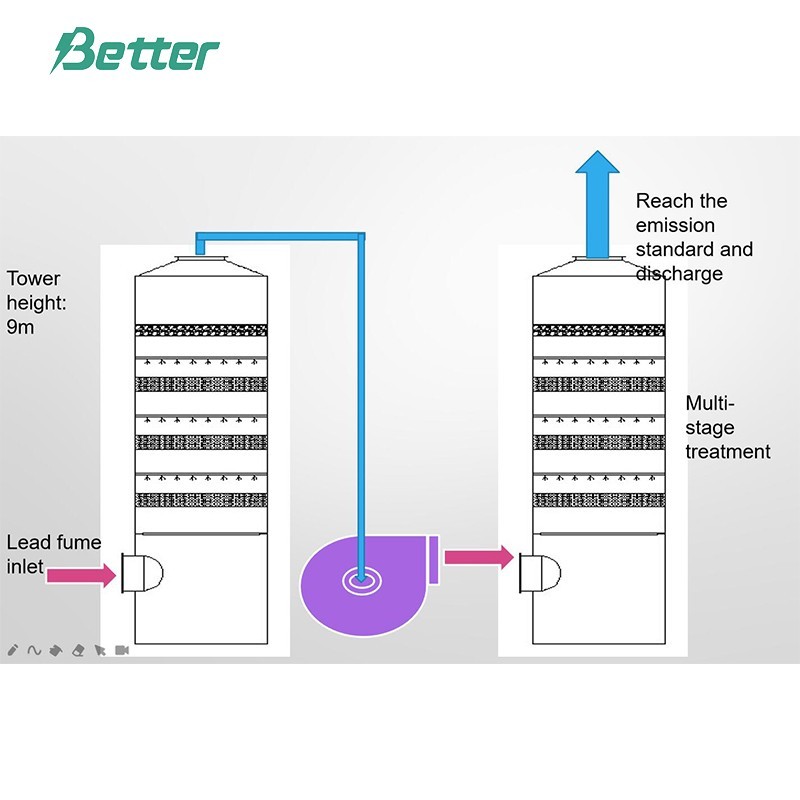

Pollution source (lead fume) → suction hood → ventilation ducting → HKE lead fume purifier →blower →VST wet scrubber → reaching the emission standard, discharging into the air

2. Working Principle:

The lead fume will go into the HKE lead fume scrubber; the HKE lead fume scrubber mainly adopts 5-level purification:

1) Level-1 purification: The lead fume inlet adopts circumferential type, the big particles dust will be removed by level-1 cyclone type, to the bottom water tank.

2) Level-2 purification: The air will go into the slotted purification section; the flow direction of air and liquid is different, reducing the liquid acceleration, overcoming the triangle spraying of co-current flow from air and liquid; the air and liquid will disperse and gather constantly, achieving good effect of medium transfer.

3) Level-3 purification: The air flow will go into the rotating-flow column plate section; the core part for air and liquid transfer adopts rotating-flow plate, which has huge superficial velocity, utilizing the centrifugal theory to make the air flow rotates after passing the rotating-flow plate; the droplet will fall to the tower wall and be separated with the centrifugal force. After condensation backflow, the air flow will continue to have rotational flow contact through the reverse rotation column plate.

4) Level-4 purification: The air will go into the turbulence porous grating, and to the packing layer. The liquid and liquid membrane will have complete transfer; some dust will flow automatically to the circulation water tank following the water flow direction.

5) Level-5 purification: The air will go through the coke adsorbed layer, the fume will be adsorbed, and some droplet will decelerate suddenly, removed by the rotating plate on the top layer of coke by centrifugal theory.

The air treated by the previous pretreatment will go into the VST wet scrubber via the blower. The lead fume will go up the first level spraying section from the bottom of the scrubber. The absorption liquid will spray out from the evenly placed nozzles; the numerous fine fog-drops will contact with the gas and have chemical reaction. The gas will go up to the packing layer. The turbulence of the small packing balls, with the wind dynamic force, will make the gaseous phase lead have chemical mass transfer reaction with the strong alkaline matter in the spray. The reacted substance will flow down to the bottom storage tank. The harmful gas which hasn’t been completely absorbed will go up to the second level spraying section. The absorption liquid will spray out from the evenly placed nozzles; the numerous fine fog-drops will contact with the gas and continue to have chemical reaction. Just like the first level absorption process, the gas will enter into the demister on the top of the scrubber. The absorption liquid contained in the gas will be cleared away and the clean gas will be discharged into the atmosphere through the exhaust chimney.

The absorption liquid can be recycling. The circulating water can be reused after treatment from the wastewater treatment plant.

Emission Standard

Pollutant | Discharging Height | Max. allowed emission concentration |

Lead and its compound | 15m | 0.50mg/m3 |

Technical Parameter

HKE Lead smoke Purification Equipment & VST wet scrubber

A3+PP structure, Q=20000m3/H, 1 set

1. HKE Lead smoke Purifier

Model: HKE-20

Air Volume: Q=20,000m3/h

Dimension: ф2000×6500mm (H)

Filtration Velocity: 1.8-2m/min

Qty.: 1pc

2. VST wet scrubber

Model: VST-20

Air Volume: Q=20,000m3/h

Dimension: ф2000×6500mm (H)

Filtration Velocity: 1.8-2m/min

Qty.: 1pc

3. Blower

Air Volume: 20000m3/h

Static Pressure: 2800Pa

Power: 30KW

Qty.: 1pc

4. Circulation Water Pump

Flow: Q=20m3/h

Stroke: 15m

Power: K=4KW

Material: Corrosion-resistant, wear-resisting

Qty.: 2pc

5. Chimney

The chimney is fixed by a Derrick

Equipped with independent detection platform and detection port

Diameter: Φ 700mm

Material: PP

Qty.: 1pc