Automatic production line for cylindrical electric tool battery pack

Automated production line for cylindrical electric tool battery packs. Enables high-efficiency assembly with ≥2400pcs/h output, 99.5% yield, and minimal manual operation (only 8 workers). Delivers reliable, precise automation using premium components for superior quality and productivity.

- Information

Equipment function

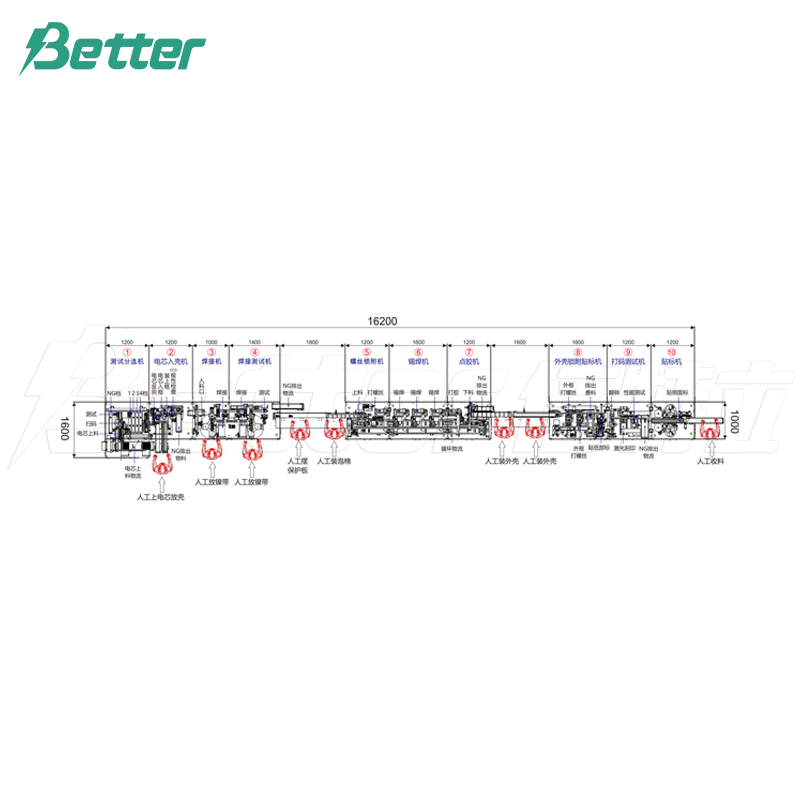

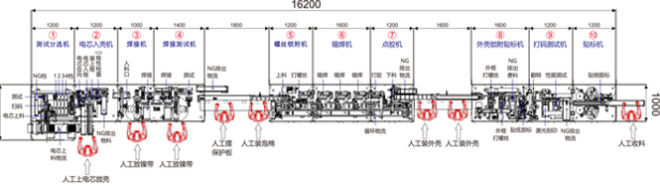

Mainly used for automaticfeeding,code sweeping,testing and grading of 18650 cores,cores into lower shell,mounting shells, CCD polarity inspection,manual nickel strips,welding,manual nickel strips,welding,testing,artificial pendulum protectiveboard, manual foaming cotton,battery wrapped screw,tin welding,gluing,manual shell shell crew,bottom.Labelling,laserengraving, performance testing,side labeling and other main production processes.According to the technological process,it can be divided intothe following 10 equipments:(1)test sorter;(2)core shellfeeder;(3)welding machine;(4)welding testing machine;(5)screw locking machine;(6)tin welding machine;(7)dispensing machine;(8)shell ock labeling machine;(9)code labeling machine;(10) labeling machine.

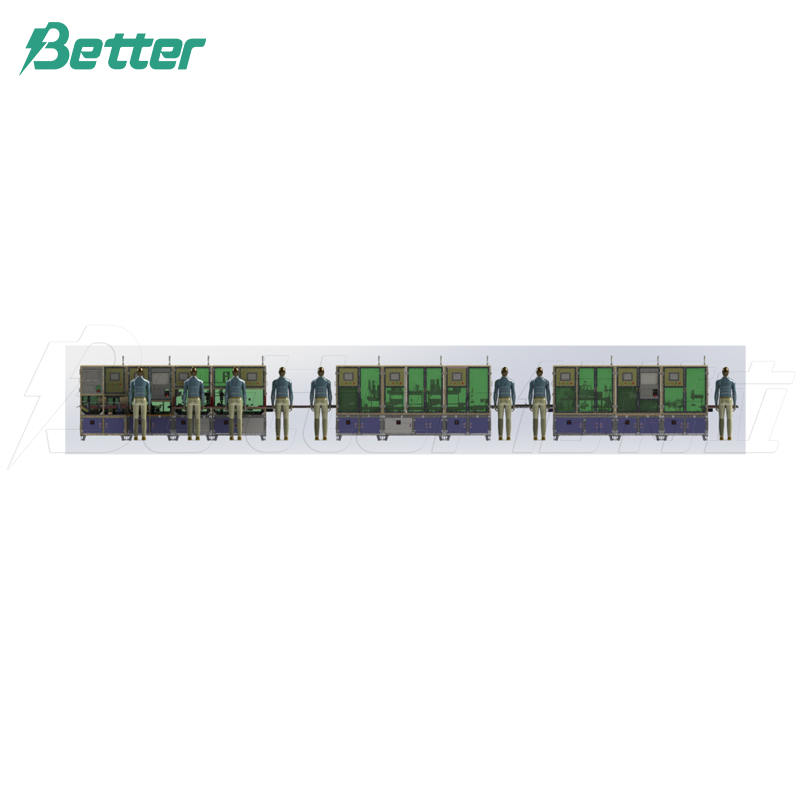

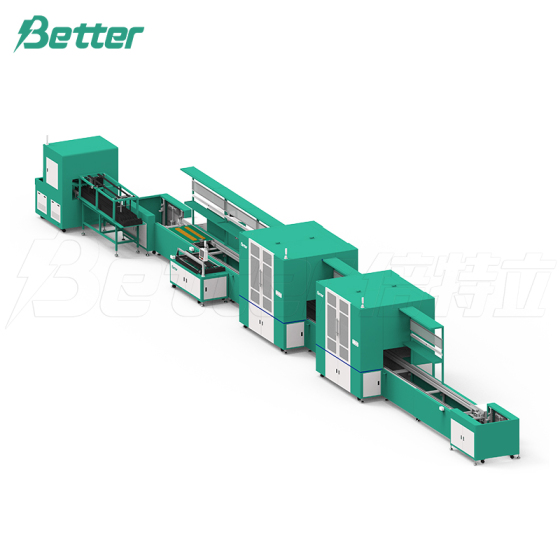

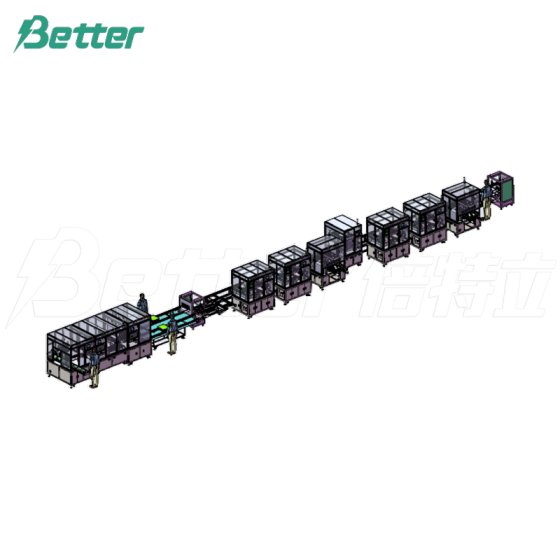

3D Appearance intention

2D layout plan

Explain

The bus body consists of8persons,one person is responsible for putting on the electric core,two persons are responsible for feeding on the nickel belt,one person is responsible for swinging the protective board,one person is responsible for foaming cotton,two people are responsible for the shell,and one person is responsible for collecting materials.

Whole line technical parameters

Supply voltage | 220V,50Hz |

Air Pressure | 0.5~0.6 Mpa |

Total power | ≤25KW |

Area bearing ratio | ≤500kg/M² |

Ambient temperature | 5C-50℃ |

humidity | 20%-90% |

Efficiency (UPH) | ≥2400Pcs/hNumber of electric core |

Equipment productivity | ≥98% |

Product qualification rate | ≥99.5% |

Outline size (without assembly line) | 16200×1500×1900mm |

Pipeline to ground height | 900mm±50m |

Brand of important components

number | Item | Brand Details |

1 | Frame | Aluminum sheet metal + surface baking varnish treatment |

2 | Module plate | 20mm Electroplated treatment, 20mm thickness |

3 | Processed parts | Aluminum components: Sandblasted and anodized surface treatment Iron components: Electroplated treatment |

4 | Human-machine interface | Exclusive to WEINVIEW |

5 | PLC | Omron, 10% port reserved |

6 | Sensor | Panasonic, Keyence, Omron |

7 | Servo motor | Panasonic, Fuji Electric |

8 | Air cylinder, solenoid valve | Airtac, SMC |

9 | Screw rod, guide rail | HIWIN, THK... |

10 | Linear motion module | HIWIN, MISUMI... |

11 | Structural standard parts | HIWIN, MISUMI... |

12 | Industrial PC | EVOC |

13 | Display screen | AOC |

14 | Electric control accessories | Chinese premium brand (CHNT, DEGSON) |

15 | Robot | Yamaha 4-axis SCARA robot |

Sample display