How to evaluate the life of lead-acid batteries...FAQ for Lead acid battery

2022-01-21 16:35

Better:High-quality export operation platform for China battery industry

1、What is lead-acid battery (Pb-A)?

Lead-acid battery, the electrode is mainly made of lead, and the electrolyte is sulfuric acid solution.

The representative symbols of lead-Acid batteries are Pb-A or L-A, in which Pb is the code name of lead in the periodic table of elements, L is the prefix of the English name Lead of lead and A is the prefix of the English name acid, both of which represent lead-acid batteries.

There are many kinds of L-A batteries, such as flat plates, spiral plate, etc.

Despite the rapid development of emerging battery industries such as lithium batteries in recent years, lead-acid batteries are still a power source with the most mature technology, the largest consumption in various fields, the largest market sales and the longest service time in the world due to their simple manufacturing process, abundant raw materials and high quality-price ratio. Lead-acid batteries used in electric bicycles belong to VRLA type, short VRLA type and square power lead-acid batteries.

2、What is gel lead-acid battery?

Electrolyte is gel, so-called gel electrolyte, which is made of gel and sulfuric acid solution according to a certain proportion by a special process, is a milky white gel. Gel is scientific, it is not easy to cause plate sulfuration, and the battery container will not leak when it is broken. Low internal resistance, low self-discharge rate, self-discharge less than 3% per month, and good capacity recovery performance: after the discharge is close to OV, short-circuit the positive and negative electrodes for 24 hours, then recharge to the termination voltage, repeat the discharge and short-circuit discharge for 5 times, and the discharge termination voltage is 10.5V. After that, the battery capacity is still greater than 90% of the rated capacity. Under normal circumstances, the service life can reach 500 times. The voltage of gel battery is 0.5~1V lower than that of modern sealed battery, and the applicable temperature is 10℃~40℃, which is relatively resistant to low temperature.

lead-acid battery making machine-Plate Strap Casting Machine(COS)

3、What standard is used for lead-acid batteries?

Battery standards are divided into three levels: national standards, industry standards and enterprise standards. At present, the automotive battery implements the industry standard numbered JB/T 10262——2001.

4、How is the lead-acid battery of electric vehicle named?

The name of automotive lead-acid battery is 6-DZM-X, where X is the suffix, and it can be 8, 10 or 12, representing the capacity of the battery. 6DZM represents a 12V valve-controlled sealed maintenance-free battery for electric vehicles is consist of 6 groups of single battery packs. If it is a colloidal battery, its labeling method is 6-DJM-X.

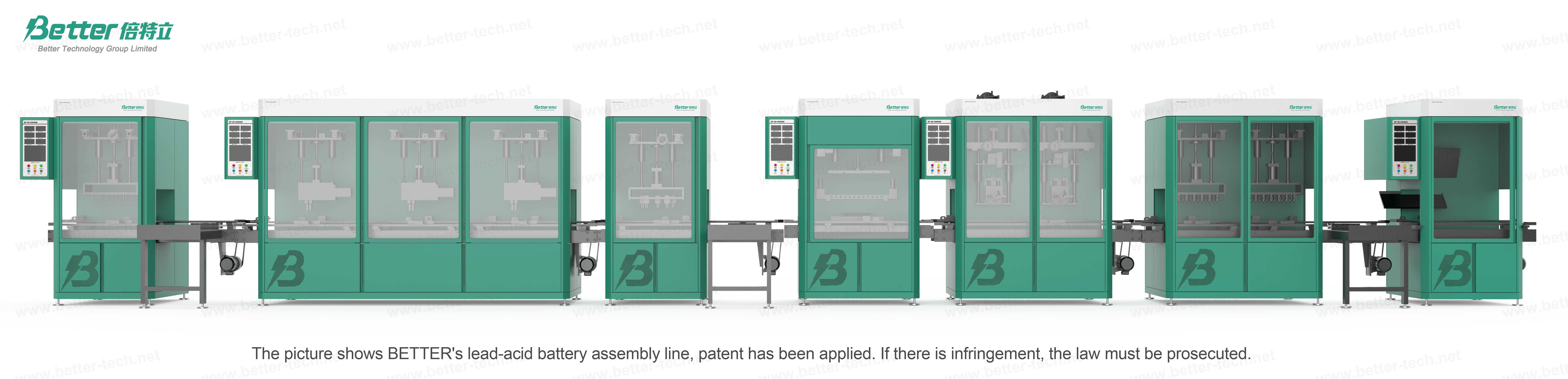

The picture shows BETTER's lead-acid battery assembly line, patent has been applied. If there is infringement, the law must be prosecuted.

5、What is the capacity labeling method of lead-acid batteries for electric vehicles?

C2 shall prevail, that is, discharge at 0.5C2 current. When the voltage reaches the cut-off discharge voltage of the battery, the product of discharge time and current shall be equal to or close to the rated capacity value. For example, a 12V, 12Ah battery is discharged at 5A current, and when the cut-off discharge voltage reaches 10.5V, the time cannot be less than 140min; Similarly, a 12V, 10Ah battery is discharged at 5A current until the voltage reaches the cut-off discharge voltage of 10.5V,The time cannot be less than 120min. The error is 0.1Ah

In fact, the industry standard stipulates that the discharge time of 10Ah battery to the cut-off discharge voltage at 5A current should not be less than 120min. The actual product reached by the enterprise is 130~137min.

6、What is the overcharge capacity of lead-acid batteries?

According to the industry standard, the lead-acid battery can be continuously charged with 1.2A current for 48h, and the actual capacity should not be less than 95% of the rated capacity.

7、What is the over discharge capacity of lead-acid batteries?

According to the industry standard, the starting discharge current of lead-acid battery is 12A±1.2A, and the continuous discharge is 2.0h with constant impedance, and the actual capacity should not be less than 75%.

lead-acid battery making machine-Plate Enveloping And Stacking Machine(PE)

8、What are the low-temperature storage characteristics of lead-acid batteries?

According to industry standards, lead-acid batteries can be stored for 10 hours at-10℃ 0.1℃, and the actual capacity can not be less than 70%.

9、 How to evaluate the life of lead-acid batteries?

When discharging at 75% of the capacity, the service life should not be less than 350 times.

10、What are the advantages of lead acid batteries?

Ultra-high quality-price ratio: the price of lead-acid batteries is 1/4~1/6 of other types of batteries. The one-time investment is relatively low and most users can afford it.

lead-acid battery making machine-Plate Curing And Drying Chamber

11、What is the relationship between the discharge rate and use of lead-acid batteries?

The same power motor, with different rated voltage, the rate of power consumption is absolutely different. For example, the same motor is 180W, and when the rated voltage is 24V, the current is 7.5A; however, when the rated voltage is 36V, the current is only 5A. They use the same capacity battery pack, the combination is 36V, discharging at 5A current, the electrochemical reaction is slow, while the combination is 24V, discharging at 7.5A current, the electrochemical reaction will be relatively intense.It's not as easy as discharging at 5A.

It is economical to discharge the battery with a current below 0.5C. What is 0.5C? C: indicates the capacity of the battery, and C2 indicates the actual capacity of the battery when discharging at a rate of 2 hours. That is to say, when C2 capacity is calibrated, half of the capacity (0.5C2) should be discharged every hour to meet the capacity requirement, and if it exceeds 0.5C2, its capacity will be reduced. But also detrimental to battery life.

At present, a battery with a capacity of 12Ah, which is marked by a discharge rate of 2 hours, should be marked as C2=12Ah, so 0.5C2=0.5×12=6A. Therefore, the 12Ah battery discharges at 0.5C, that is, the current is 6A.

If the battery works for a long time, the output working current should not be greater than the rated capacity Cx /X, x is the time rate under the rated capacity of the battery, which is the selection principle. when the value of X is 2, the discharge rate should be 2 hours; If the value of x is 3, the service time should be considered as 3 hours.

lead-acid battery making machine-Battery Acid Filling Machine

12、What are the marking methods of lead-acid battery capacity at present?

At present, there are several marking methods for the capacity of lead-acid batteries, such as C20, C10, C5 and C2, which respectively represent the actual capacity obtained when discharging at the discharge rates of 20h, 10h, 5h and 2h. If it is the capacity at a discharge rate of 20 hours, the label should be C20,C20=10Ah battery, which refers to the capacity value obtained by discharging at a current of C20/20 for 20 hours. Converted to C5, that is, discharged at four times of C20 specified current, the capacity is only about 7Ah.Generally, the electric bicycle will discharge at a high current within 1~2h, and the lead-acid battery will be discharged within 1~2h(C1~C2), which is close to 10 times of the specified current, so the electric energy it can actually supply is only 50% ~ 54% of C20 discharge capacity. The battery capacity is marked C2, that is, the capacity marked at the rate of 2h discharge. If it is not C2, it should be calculated to get the correct discharge time and capacity. If the capacity indicated by 5h discharge rate (C5) is 100%, the actual capacity is only 88% if it is discharged within 3h instead. After 2 hours, only 78%; after discharging in 1 hour, only 65% of the capacity when discharging in 5 hours remains. If the marked capacity is 10Ah, only 8.8Ah of actual electricity can be obtained by discharging at 3 hours; If it is discharged for 1 hour, only 6.5Ah of electricity can be obtained, and the discharge rate can be arbitrarily reduced, the discharge current is greater than 0.5C2 not only reduces the capacity than indicated, but also has a certain influence on the battery life. Similarly, for the battery marked (rated) as C3, the discharge current is C3/3, that is, ≈0.333C3, if it is C5, the discharge current should be 0.2C5, and so on.

13、What are the characteristics of secondary lead-acid batteries?

Common characteristics of secondary batteries When charging, the negative electrode produces gas, which surrounds the negative electrode and prevents electrons from reaching the negative electrode for electrochemical reaction, which not only affects the charging efficiency, but also causes plate heating, electrolyte evaporation and drying up, and concentration change. Evaporation and thickening of electrolyte in lead-acid battery will promote the vulcanization of polar plates, reduce the charging efficiency and capacity, and finally cause the battery scrapping.

All batteries should not be over-discharged. Over-discharge is at the expense of shortening the service life, and the discharge should be not lower than the cut-off discharge voltage.

Battery Separator

14、Why do lead-acid batteries need to be completely discharged once a month?

If the lead-acid battery is in the state of incomplete discharge for a long time, it should be given a chance of complete discharge once a month to keep the activity of the battery plate material. Complete discharge can run for a long distance until the controller is under-voltage protected and automatically turned off.

15、What are the unfavorable factors for lead-acid batteries?

There are many unfavorable factors for the battery, mainly occurring in the charge-discharge stage.

(1)The 'second overload' discharge stage is mainly the excess discharge current, that is, the discharge that exceeds the allowable current value for a long time; The second problem of discharge is overdischarge, that is, the discharge capacity that exceeds the battery's allowed capacity, called 'second excess', which is very harmful to battery life.

(2)In the charging stage there are 'two passes' and 'two lacks'.

* 'two passes':

First pass is overcharge; Second pass is over storage of lead-acid batteries , and not replenished regularly.

*'two lacks':

one lack is that the lead-acid battery is lack of charging, which cause the plate cannot be restored in time after vulcanization, it is extremely bad for maintenance lead-acid batteries; Another lack is that the single cells in the battery pack are unbalanced, which causes the gap between the discharge degree and the charging degree among the single cells in a group of batteries to become larger and larger, and the situation of lack of charging and overdischarge become more worst. Affect the life of the entire battery pack, but also increase their own economic expenditure.

'Two-passes' and 'two-lacks' are the 'enemy' of batteries, which should not be underestimated. However, the 'two passes' and 'two lacks' are caused by people themselves, and the problems are complicated. There are many reasons from type selection, use and maintenance, matching rationality of controller and charger, and timely detection of battery failure.

16、What is the reason for the temperature increase after the new lead-acid battery is added with electrolyte?

After adding electrolyte into the new battery, the temperature rise is related to the internal factors of the new battery. The temperature of dry-charged battery rises after adding electrolyte, but the temperature rise of the battery is not very obvious. Because the dry-charged electrode plate has been treated with oxidation resistance8, and fully charged before leaving the factory, which can be used after adding liquid. The battery with ordinary plate, without anti-oxidation treatment, has a semi-fully charged negative plate. A considerable number of substances are in a position to generate a large amount of heat for the reaction between lead oxide and dilute sulfuric acid, so the temperature is very high. Sometimes the temperature is above 50℃ in summer, so pay attention to artificial cooling when charging.

17、Can lead-acid batteries be supplemented with distilled water?

Valve-regulated sealed maintenance-free lead-acid battery is different from other batteries. In fact, it can't be completely maintenance-free. It can only reduce the maintenance workload, with less electrolyte evaporation and no leakage. Since the charger has not reached the completely ideal level, a small amount of water evaporation cannot be avoided. For users who have a little knowledge of batteries, when the capacity is obviously reduced, can consider adding water properly to restore the original concentration of electrolyte or lower than the original concentration, which is more beneficial to the plate.

Battery Charging And Discharging Machine

18、What are the main components of lead-acid battery electrolyte?

It is a mixture of sulfuric acid and distilled water (or deionized water).

19、What kinds of common lead-acid battery container (case) are there?

Common battery containers include car, motorcycle and traction battery which made of hard rubber and polypropylene, sealed battery containers made of ABS and a few polystyrene.

20、What are the common separators of lead-acid batteries?

Common battery separators include rubber separator, PP separator, PE separator, PVC separator and AGM separator.

21、What are the alloys commonly used in lead-acid battery manufacturing?

The alloys used to manufacture lead-acid batteries mainly include lead-antimony alloy, lead-low antimony alloy, lead-antimony-cadmium alloy and lead-calcium alloy.

Battery Plate

22、What are the charging methods of lead battery?

There are mainly constant current charging, constant voltage charging, constant current limited voltage charging, balanced charging, floating charging and pulse fast charging.

23、What is the relationship between electrolyte density and open circuit voltage of lead-acid battery?

Open circuit voltage =0.85+ electrolyte density (empirical formula)

24、What does the plate capacity of lead-acid battery depend on?

Mainly depends on the amount of active materials on the positive and negative plates.

25、What are the main components of active materials in the positive and negative plates of lead-acid batteries?

The main component of positive plate active material is lead dioxide, and the main component of negative plate active material is sponge lead.

26、Why does the lead battery have a pungent smell when charging?

During the charging process of the battery, the mixture of sulfuric acid steam, water vapor, hydrogen and oxygen generated inside the battery diffuses into the air, which will make people smell the pungent smell.

27、What is floating charge and balanced charge of lead battery?

Floating: A lead acid battery that supplies power to a circuit when normal power supply is interrupted. Its terminal is always connected to the constant voltage power supply to keep the battery in a nearly fully charged state.

Balanced charging: a kind of continuous charging to ensure that all the single batteries in the battery pack are fully charged.

28、What is the reason for the temperature increase after the new lead-acid battery is added with electrolyte?

After adding electrolyte into the new battery, the temperature rise is related to the internal factors of the new battery. The temperature of dry-charged battery rises after adding electrolyte, but the temperature rise of the battery is not very obvious. Because the dry-charged electrode plate has been treated with oxidation resistance8, and fully charged before leaving the factory, which can be used after adding liquid. The battery with ordinary plate, without anti-oxidation treatment, has a semi-fully charged negative plate. A considerable number of substances are in a position to generate a large amount of heat for the reaction between lead oxide and dilute sulfuric acid, so the temperature is very high. Sometimes the temperature is above 50℃ in summer, so pay attention to artificial cooling when charging.

29、What are the reasons for sulfation of lead-acid battery uncharged plates?

There are several reasons for plate sulfation:

1) the initial charge of the battery is insufficient or the initial charge interruption time is long;

2) The battery is under-charged for a long time;

3) Failure to charge in time after discharge;

4) Frequently overcharge or low current deep discharge;

5) If the electrolyte density or the temperature is too high, lead sulfate will be deeply formed and difficult to recover;

6) The battery has been put on hold for a long time, and has not been used for a long time without regular charging;

7) The electrolyte is impure and self-discharge is large;

8) Local action of internal short circuit or water on the battery surface causes leakage;

9) The electrolyte volume inside the battery is low, so that the exposed part of the plate is sulfated.

30、 What are the requirements for storage of lead-acid batteries?

It is required that the ventilation facilities should be good and dry (with air conditioning is best), and the environment temperature should be kept around 25℃; Strong ground bearing capacity; After 3 months of storage, it should be recharged.

"Good quality battery need good equipment", Better Technology Group Limited, which is mainly specialize in lead acid battery production equipment, raw materials and spare parts. Focused on development for over ten years,With rich experience in battery manufacturing and mechanical manufacturing in the lead-acid battery industry, takes the lead in productizing solutions,Adhering to high-end equipment and high-quality services, It is a rare manufacturer which a battery Manufacturing Solution Expert and Resource-rich Operator. We has created “China's First Station” and became the "Purchasing Center in China" for many international customers, Has thoroughly solved problems including the long project construction period, the heavy technical connection task, unreasonable production line matching, and cumbersome business communication arising from purchasing from multiple sources by customers.

Now, Better Technology Group Limited owns two major brands, BETTER and WELLPACK, which are mainly engaged in lead acid battery and lithium battery respectively and create professional connection between lead acid battery resources and lithium battery. The company not only provides customers with equipment, batteries, raw materials, auxiliary materials, related accessories, battery production technology output and other related businesses, but also focuses on the research, development, production and sales of various high-end lithium ion batteries, as well as the development of diversified customized lithium battery application solutions. The application scope covers consumer electronics, toys, power tools, automobiles, electric vehicles, energy storage systems and other fields.