- Home

- >

News

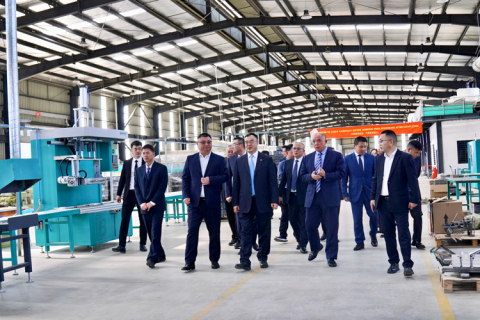

Recently, Wellpack New Energy Technology (referred to as Wellpack), a domestic subsidiary of Better Technology Group Limited (referred to as Better Tech Group), held its MES project kickoff meeting under the theme "Powering Progress Through Digital Intelligence" at the group's factory. Senior leadership, R&D, technical teams, and project partners attended the meeting.

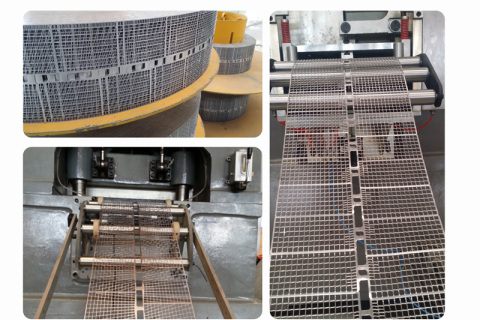

The Punching line machine is far more than a simple press. It’s a sophisticated, integrated system engineered for the express purpose of producing high-quality battery grids efficiently and consistently. By automating the journey from raw lead strip to finished grid, it plays a vital role in streamlining the battery assembly line and forms the foundation for reliable, high-performance lead-acid batteries. Investing in such technology is key for manufacturers focused on quality and competitive production.

Sealed lead-acid (SLA) batteries are widely used in various applications, including backup power systems, electric vehicles, and industrial machinery.

The battery manufacturing process consists of several crucial stages, each requiring precision and efficiency to ensure high-quality output

Lead-acid batteries have been the go-to solution for many energy storage needs for more than a century, thanks to their reliability, cost-effectiveness, and long-lasting performance.

With continuous technological advancements and fluctuating market demands, fully automatic battery assembly lines are also evolving and innovating. The following are future development trends:

Fully automatic battery assembly lines possess extensive application prospects across multiple industrial domains. As battery technology progresses and market demand escalates, battery production equipment persists in innovating and advancing.

These assembly lines are extensively utilized in the manufacturing of lead-acid batteries, including those for motorcycles, automobiles, and industrial applications. Their efficiency and scalability render them ideal for meeting variegated market demands