How Lithium-Ion Battery Manufacturing Works

2026-02-10 11:46Table of Contents

1. The Basics of Lithium-Ion Batteries

2. Raw Materials in Battery Production

3. Making the Electrodes

4. Cell Assembly Options

5. Electrolyte Filling and Sealing

6. Formation and Initial Charging

7. Quality Testing and Safety Checks

8. Common Challenges in Production

9. Boosting Efficiency with Modern Equipment

The Basics of Lithium-Ion Batteries

Lithium-ion batteries power most of the devices people use every day—phones, laptops, electric vehicles, and power tools. What makes them so widely used is their ability to store a lot of energy in a small, lightweight package while lasting through hundreds of charge cycles.

In simple terms, a lithium-ion battery works by moving lithium ions between a positive electrode (cathode) and a negative electrode (anode) through an electrolyte. During charging, ions travel one way and electrons flow through the external circuit to store energy. During discharge, the process reverses to release that energy.

The entire battery manufacturing process is designed around keeping this ion movement efficient, safe, and consistent. Modern lithium-ion battery manufacturing happens in highly controlled clean-room environments to avoid contamination, which can ruin performance or cause safety issues.

Raw Materials in Battery Production

Everything starts with the raw materials. The cathode is usually made from lithium metal oxides—common choices include lithium nickel manganese cobalt (NMC) or lithium iron phosphate (LFP). These materials determine energy density, safety, and cost.

The anode is most often graphite, sometimes mixed with silicon for higher capacity. A thin polymer separator keeps the electrodes apart while letting ions pass through. The electrolyte is a lithium salt dissolved in organic solvents that carries the ions.

Current collectors—aluminum foil for the cathode and copper foil for the anode—complete the basic structure. All these materials must be extremely pure. Even tiny impurities can lead to reduced performance or internal short circuits later on.

In battery manufacturing, sourcing consistent, high-purity materials is one of the biggest cost and quality factors.

Making the Electrodes

Electrode production is where most of the precision work happens in lithium-ion battery manufacturing.

Manufacturers first mix active materials with binders and conductive additives into a slurry. This slurry gets coated evenly onto the metal foils—aluminum for cathodes, copper for anodes. Coating thickness directly affects capacity and charging speed.

After coating, the wet electrodes pass through long drying ovens to remove solvents. Then they go through calendering rollers that compress the coating to the right density. Higher density usually means better energy storage, but it must be balanced to avoid blocking ion pathways.

Finally, the wide coated foils are slit into narrow strips sized for the specific cell format. Any burrs or uneven edges at this stage can cause problems during assembly, so precision slitting is critical.

Modern battery manufacturing lines run these steps continuously at high speed to keep costs down while maintaining tight tolerances.

Cell Assembly Options

Once electrodes are ready, the cell takes shape. There are three main formats: cylindrical, prismatic, and pouch.

Cylindrical cells (like 18650 or 21700) use a winding process. The anode, separator, cathode, and another separator are layered and wound into a jelly-roll that fits inside a metal can.

Prismatic cells are also wound but pressed into a rectangular shape. Pouch cells, common in phones and many EVs, use stacking instead of winding. Individual anode and cathode sheets are alternated with separator layers to form a stack.

Stacking allows slightly higher energy density and better heat dissipation, but it requires very precise alignment. For pouch cells, tabs are welded to connect all the layers electrically, and the stack is placed into a flexible aluminum-laminated pouch.

In soft-pack battery manufacturing, additional protective steps—like precise taping or lamination at the cell head—are needed to prevent damage and ensure long-term reliability.

Electrolyte Filling and Sealing

After assembly, the cell is filled with electrolyte in a dry room (dew point often below -40°C) because lithium salts react with moisture.

Filling must be exact—too little reduces performance, too much can cause swelling or leaks. For pouch cells, the process happens under vacuum to remove air and help electrolyte penetrate the stack.

Once filled, the cell is sealed. Cylindrical and prismatic cells get crimped metal lids with safety vents. Pouch cells are heat-sealed around the edges, leaving one area temporarily open for gas release during formation, then permanently sealed later.

Sealing quality is crucial—any leak allows moisture in, which can destroy the battery over time.

Formation and Initial Charging

Every new lithium-ion cell goes through formation. This is a controlled first charge-discharge cycle that creates a stable solid electrolyte interphase (SEI) layer on the anode. The SEI layer is essential for long-term stability.

Formation is slow and temperature-controlled, often taking hours or days. It generates some gas, which is removed in a degassing step for pouch cells.

After formation, cells typically reach over 1000 full charge cycles with proper design, though real-world life depends on usage.

Quality Testing and Safety Checks

Before shipping, every cell undergoes electrical testing—capacity, internal resistance, voltage consistency. Many manufacturers also run sample destructive tests and accelerated aging.

Safety features are built in: pressure vents, shutdown separators that melt to block ion flow at high temperature, and sometimes ceramic coatings on separators for extra protection.

Modern lithium-ion battery manufacturing includes multiple inline inspection points using X-ray, optical scanning, and AI vision systems to catch defects early.

Common Challenges in Production

Scaling battery manufacturing while keeping costs low and quality high is tough. Contamination control requires expensive dry rooms. Material prices—especially lithium, cobalt, and nickel—fluctuate widely.

Yield rates matter hugely. A small drop from 99% to 95% can make a factory unprofitable. Heat management during fast coating and drying lines needs careful engineering.

Safety remains the top priority. Even rare failures get massive attention, so processes are designed with multiple redundant safeguards.

Boosting Efficiency with Modern Equipment

As demand for lithium-ion batteries grows, factories are turning to highly automated equipment to improve speed, precision, and yield.

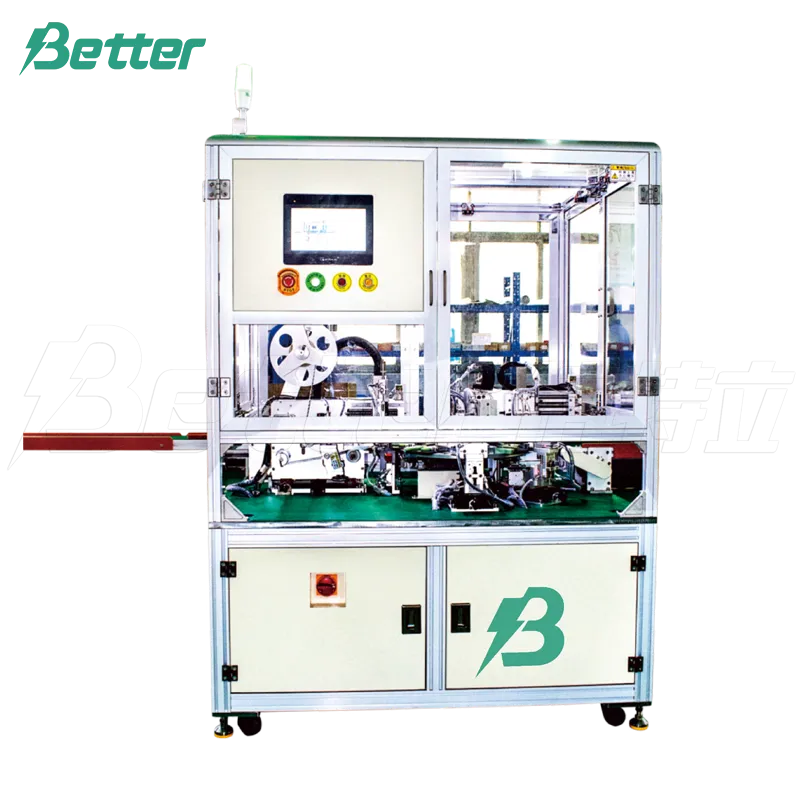

For manufacturers working with soft-pack cells, a reliable glue laminating machine can make a big difference in the protective taping step. The Glue Laminating Machine from Better Tech automates precise head taping with ±0.25mm accuracy, eliminates bubbles and wrinkles, and reaches production rates of ≥1000 pieces per hour while maintaining a ≥99% yield rate. Its anti-static design and vacuum monitoring help protect sensitive cells, and the intuitive controls make model changes straightforward. These features add up to better protection, fewer defects, and higher throughput—exactly what growing battery manufacturing operations need.