How Does a Lead Oxide Filling Machine Boost Battery Production?

2025-09-04 17:20For businesses in battery manufacturing, picking the right equipment can make or break your production line. The Lead Oxide Filling Machine from Better Technology Group Limited is designed to streamline the process of filling lead oxide into tubular battery plates, especially for 6V and 12V electric vehicle batteries. It's not just about getting the job done—it's about doing it efficiently, with options that match your specific needs.

What is Lead Oxide Filling and Why It Matters

Let's break down what lead oxide filling is and why it's so important. In lead-acid batteries, lead oxide forms the active paste that powers the battery's performance, affecting its capacity and durability. Properly filling this material into the plates ensures the battery works well over time. Uneven or sloppy filling can lead to weak performance or early battery failure, which no manufacturer wants.

The Lead Oxide Filling Machine tackles this with precision. It delivers a filling density of 3.6 grams per cubic centimeter, perfect for reliable battery output. It also maintains an 80% consistency rate, meaning most plates stay within a tight 10-gram range for 6V or 12V setups. This kind of accuracy keeps your production smooth and reduces costly mistakes.

Standout Features for Better Production

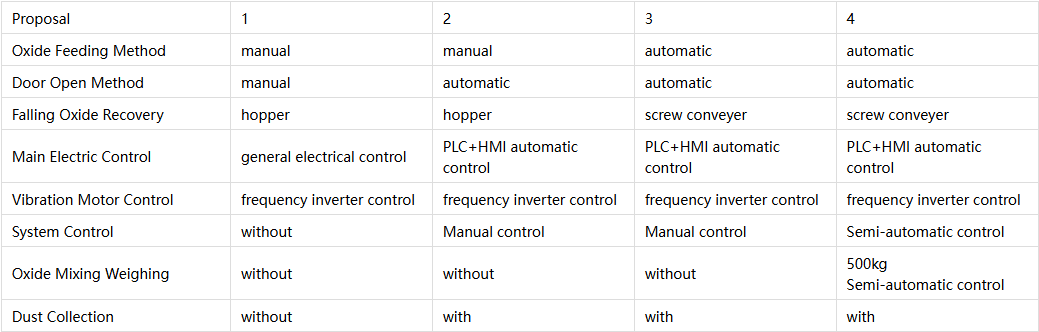

What makes this machine special is its flexibility. You get four different configurations to choose from, each tailored to different operational scales. For example, you can go with manual or automatic oxide feeding, depending on your team's size and workflow. The door operation can also be manual or automatic, giving you more control over the setup.

The control systems range from simple manual options to advanced PLC and HMI setups, letting you adjust vibration settings with a frequency inverter for optimal results. Worried about workplace safety? The machine's negative pressure vent ensures a sealed operation, keeping dust under control and the environment cleaner for your crew.

In terms of speed, it fills 45 plates in about three minutes, which translates to roughly 5,000 plates in an eight-hour shift. That's a serious boost to your output without compromising quality.

Tailored Options for Your Factory

Every production facility is unique, and the Lead Oxide Filling Machine is built with that in mind. If you're running a smaller operation, Proposal 1 offers a manual setup that's cost-effective yet reliable. For larger setups, Proposal 4 includes a high-capacity oxide mixing and weighing system that processes 500 kilograms in just 10 to 15 minutes.

Dust management is a big plus, especially in Proposals 2, 3, and 4, which include dust collection via a hopper or screw conveyor. This cuts down on waste and keeps your workspace safer. Whether you're dealing with tight space or specific production needs, these options let you customize without overhauling your entire line.

For companies sourcing battery production tools, this machine fits right into existing setups. Backed by Better Tech Group's 30+ years of expertise, it's a dependable choice for global markets, from BRICS nations to beyond.

Common Concerns in Battery Manufacturing

How does this machine stack up against older methods? Manual filling is slow and often inconsistent, leading to higher defect rates. The Lead Oxide Filling Machine automates the process, saving time and reducing errors. Maintenance is another common concern—it's designed for minimal upkeep, with easy-to-adjust controls and a sealed system that cuts down on cleaning time.

Dust can be a headache in many factories, but the advanced proposals include built-in collection systems that recycle oxide and keep the air cleaner. The machine's 320mm filling length is also perfectly suited for standard tubular plates, so you won't run into compatibility issues.

In short, the Lead Oxide Filling Machine is more than just equipment—it's a tool to help your business thrive. With its mix of efficiency, adaptability, and reliability, it's built to meet the demands of modern battery manufacturing. If you're looking to level up your production, this machine is worth exploring.