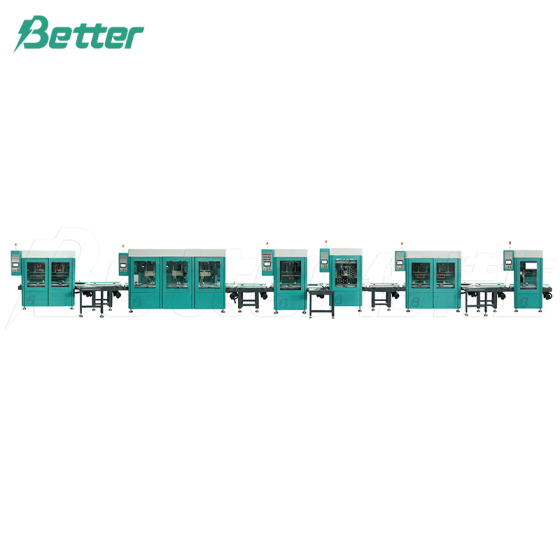

Epoxy Dispensing Machine

Epoxy Dispensing Machine for VRLA Batteries. Automates precise epoxy sealing of lids and terminals with dual-station efficiency, ±3% accuracy, automatic cleaning, anti-curing system, and leak-proof results for reliable, high-quality production.

- BETTER

- CHINA

- Information

- Video

Introduction

Model: BP580-B2 (double systems metering)

Production Capacity: 12V100Ah, 200pcs/hr

Dimension (L*W*H): 1800mm×1100mm×1800mm

Applicable Epoxy/Glue: epoxy for cover dispensing

1.5 Proportion: 100:100~100:10, adjustable

Working Range: 600 (X)* 600 (Y)* 100 (Z) mm

Station: double stations, each station size is 300 (W)*600(L)*80(H)

Proportion Accuracy: ±3%

Glue Output Accuracy: ±3g (when the glue output volume is >1g)

Metering method: servo motor + gear pump

Transmission method: servo motor

Power: AC380V, 50HZ, 0.5-1.5KW

Working temperature: Moisture 20~90%, Temperature 0~40℃

Equipment Composition

Frame: composed of heavy load type aluminum profile; surface is with electrophoresis treatment; color is silvery, sheet metal is dark blue.

The glue barrel is equipped with pressure vacuum, barrel material is SUS304.

2 groups (4pcs) precision metering gear pump as glue output control module

Dispensing gun module

Automatic cleaning module

Automatic electrical control module

Principle

The machine is controlled by the PLC, the human-machine interaction and parameters setting and recall is through the touch screen. The epoxy is output quantitatively with the force of the servo motor by driving the precision metering gear pump, and the AB epoxy is mixed by the static mixing module, achieving the dispensing by the dispensing gun module.

Features

Diversified selection for the working method: the user can select dispensing by fixed point, fixed volume or by timing.

Most of the material is made of SUS304 stainless steel and aluminum profile, easy for keeping clean and maintenance.

With anti-curing system: When the machine is stopped, it will dispense the epoxy auto-timing quantitatively, preventing the dispensing tube from being solidified and blocked.

With automatic cleaning system: Start the auto cleaning procedure, the nozzles will automatically move to the cleaning point and finish the cleaning.

With high-accuracy three-axis manipulator for dispensing, the range is (X) 600mm* (Y) 600mm *(Z)100mm, repeated accuracy ±0.02mm;

With vacuum mixing barrel, providing vacuum suction for feeding uninterruptedly.

With function of constant temperature heating

The glue output system is equipped with automatic suction function, ensuring there is no redundant epoxy.

The epoxy outlet has Y-shape filter valve, preventing other thing from entering into the pump body.

When there is blockage in the tube, there is over-pressure protection, in case that the tube will crack and the connector will fall off.

The procedure will terminate or alarm when there is no air pressure or when the air pressure cannot meet the requirement.