Dispensing Machine for Black and Red Epoxy

Dispensing Machine for Black and Red Epoxy is controlled by the PLC, the human-computer interaction and parameters setting and recall is through the touch screen. The glue is output quantitatively with the force of the servo motor by driving the precision metering gear pump, and the AB epoxy is mixed by the static mixing module, achieving terminal dispensing by dispensing guns module.

- BETTER

- China

- Information

1. Technical Parameters

1.1 Dimension (L*W*H): 780mm×700mm×1820mm

1.2 Power Required: AC220V, 50HZ, 1.5KW

1.3 Compressed Air: >5kgf/cm2

1.4 Production Capacity: about 1800pcs/hour (1pc / 2 seconds), depends on the operation skill

1.5 Applicable for dispensing epoxy for all the battery terminals

1.6 Applicable Epoxy: terminal epoxy

1.7 Proportion: 100:100~100:20, adjustable

1.8 Proportion Accuracy: ±2%

1.9 Ration Glue Volume: 0.3g, 0.8g

1.10 Ration Glue Output Accuracy: ±0.1g

1.11 Glue Output Speed: 0~7g/s

1.12 Anti-curing Time: 0~600s

2. Equipment Composition

2.1 Frame: composed of heavy load type aluminum profile; surface is with electrophoresis treatment; color is silvery, sheet metal is dark blue.

2.2 Pressure vacuum material barrel with mixing; Material: SUS304 stainless steel

2.3 1 group (2pcs) of precision metering gear pump glue output control module

2.4 Manual control output or ration output can be selected.

2.5 Dynamic mixing or static mixing can be selected.

3. Principle

The machine is controlled by the PLC, the human-computer interaction and parameters setting and recall is through the touch screen. The glue is output quantitatively with the force of the servo motor by driving the precision metering gear pump, and the AB epoxy is mixed by the static mixing module, achieving terminal dispensing by dispensing guns module.

4. Features

4.1 Easy for operation, there are two ways of dispensing, i.e. ration dispensing & manual control dispensing.

4.2 The dispensing system adopts servo motor with high-precision gear wheel metering pump, achieving dispensing quantitatively in constant proportion. Mixing and Dispensing will work at the same time, saving glue effectively.

4.3 The glue proportioning range is wide (100:10~100:20), the accuracy is ±2%.

4.4 With vacuum type mixing barrel, the glue can be supplied uninterruptedly and recurrently.

4.5 Reasonable design for easy maintenance, with function of anti-curing and cleaning.

4.6 The glue barrel and pipeline are made of stainless steel, with function of constant temperature heating.

4.7 With level switch in the glue barrel, the system will alarm if the epoxy is less/empty.

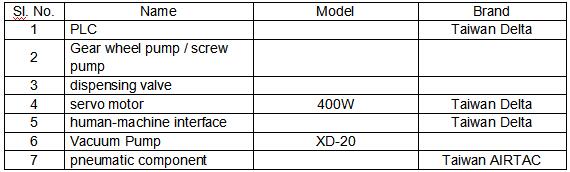

5. Configuration of the Main Parts: