Preventive measures for lead-acid battery leakage & Classification of battery parameters

2022-04-13 18:09

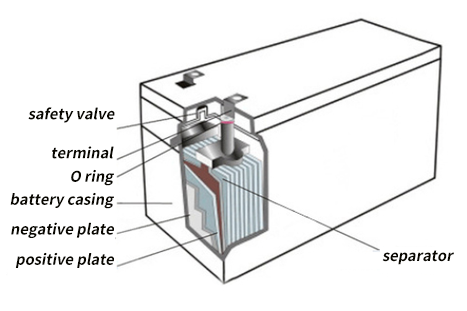

Internal structure diagram

01 Electrolyte

The high-power lead-acid battery is maintenance free, and electrolyte is not needed to be added in the later maintenance of the battery. In the production process, the non-flooded solution technology is generally used. The O2 produced by the positive electrode reaches the negative electrode through the AGM separator for composite absorption. If the amount of electrolyte in the battery is too much and the pressure increases, resulting in the blockage of the composite channel, the gas pressure inside the battery will be increased, make the battery leak at the place with poor sealing.

02 Safety valve

Battery with safety valve

Firstly, the acid filling amount of the battery is too much, and the battery is in flooded state, resulting in the blockage of the gas channel of O2 regeneration, and the gas generated by the battery can not be combined. After the internal pressure increases, the safety valve opens frequently. After the gas overflows the safety valve, it gets cold outside the battery and condenses into acid liquid around the safety valve;

Secondly, the rubber pad around the safety valve is aging, and the sealing performance of the battery changes, resulting in the pressure drop of the valve opening. After the safety valve is opened for a long time, the acid mist condenses into liquid and causes liquid leakage.

03 Post terminal

The phenomenon of post leakage is common in the data center room. After the battery has been running for one year, some pole terminals will leak. After five years of operation, the problem of leakage is very serious. The key reason of battery leakage is that the post metal and battery cover sealant do not match well, the post terminal is corroded by oxygen in acidic environment, and the electrolyte is under the action of internal pressure, along the corrosion path, it flows to the surface of the terminal to produce leakage, which is commonly known as creeping acid phenomenon.

04 battery casing and cover

At present, there are two ways to seal the battery casing and cover: epoxy resin sealing and heat sealing.

The leakage of epoxy resin sealant is mainly due to the strict control conditions of sealing, and the epoxy adhesive formula and curing conditions are required to be controlled well. Otherwise, the adhesion between the sealant and the shell will not be well combined, forming a leakage channel and causing battery leakage;

Preventive measures for leakage of high power lead-acid battery

In order to solve the problem of battery leakage, the most important thing is to ensure the quality of lead-acid battery, such as ensuring that the amount of electrolyte in the battery is in a reasonable range, ensuring the sealing of the battery shell, and ensuring the effectiveness of the sealing of the battery casing and cover.

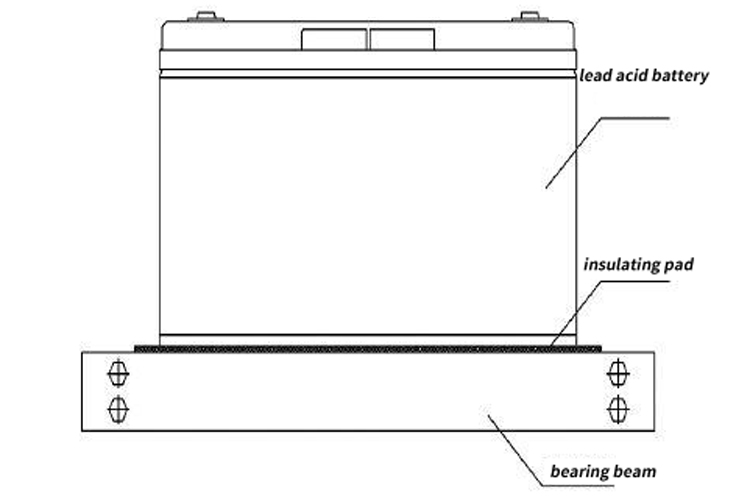

Installation Diagram of Insulating Pad

01 Insulating pad

Installation of insulating pad in data center room is the simplest and effective method to prevent short circuit of high-power lead-acid battery, to prevent electrical short-circuit caused by conductive between corrosive liquid flowing out of battery leakage and metal frame at the bottom of battery. The installation diagram is shown in Fig. 1.

This measure is easy to implement and has a certain effect on the vertically installed batteries,

At present, there are two kinds of insulation pads: flame retardant rubber pad and epoxy resin board.

The flame retardant rubber pad is made of rubber, and the flame retardant is added into the material to achieve the flame retardant effect. The rubber pad has high elasticity, so its seismic performance is particularly good; rubber insulating pad has high surface resistance, difficult installation and poor heat dissipation performance, but its price is relatively cheap.

The material of epoxy resin pad is epoxy board, also known as glass fiber cloth. It is bonded with epoxy resin and made by heating and high pressure. It has high mechanical performance at medium temperature and stable electrical performance under high humidity. It is used to prevent electrical short circuit caused by battery leakage, and the effect is very significant. Relatively speaking, the surface of epoxy insulation board is smooth and easy to install, but the price is more expensive than rubber pad.

02 Insulating sheath

The metal load-bearing beam shall be fully wrapped as shown in Fig. 2 to prevent the leakage of corrosive liquid from connecting the battery and the rack, resulting in electrical short circuit. Insulating sheath can also be called U-shaped slot or bearing beam sheath.The material is flame retardant PVC, ABS or PP, which is smooth, wear-resistant, pressure resistant and easy to install. And it does not affect the ventilation and heat dissipation of the upper and lower layers of the battery. The disadvantage is that it cannot take liquid, the amount of liquid will flow to the lower battery to produce corrosion. The insulating sheath needs to be customized according to the shape of bearing beam.

03 Leak proof tray

The tray thickness design should have certain strength to bear the battery weight; a guide bar is designed at the bottom of the tray to make the electrolyte diffuse to the tray, so as to avoid excessive deposition of electrolyte at one place and make the battery soak in the electrolyte for a long time; the pallet material is flame retardant ABS or other flame retardant plastic materials to ensure the flame retardant performance of the pallet, to some extent, it can prevent the battery from burning due to electrical short circuit. The disadvantage is to customize the plastic mold for each type of battery. The installation diagram of leakage proof tray is shown in Fig.

In recent years, the accident in data center room caused by lead-acid battery leakage is not rare, and the leakage of the whole system caused serious harm.Therefore, in the daily maintenance of data center room, it is necessary to understand the harm, causes and countermeasures of lead-acid battery leakage.

Main parameters of battery

Battery capacity is the amount of energy stored in the battery, represented by the symbol C.The common unit is ampere hour, abbreviated as ampere hour (Ah) or milliampere hour (MAH).

The capacity of battery can be divided into rated capacity (nominal capacity) and actual capacity.

(1) Rated capacity

The rated capacity is that the battery is required to discharge at a rate of 10 hours at an ambient temperature of 25 ℃, and should discharge the minimum amount of electricity (Ah).

(2) Actual capacity

The actual capacity refers to the power output of the battery under certain conditions. It is equal to the product of discharge current and discharge time, the unit is Ah.

02 Energy

The energy of battery refers to the electric energy that the battery can provide under a certain discharge system, usually expressed in watt hour (WH).

03 Cycle life

The battery experiences a charge and discharge, which is called a cycle. Under certain discharge conditions, the number of cycles that the battery can withstand before it works to a certain capacity is called cycle life.

The traditional stationary lead-acid battery is about 500 ~ 600 times, and the starting type lead-acid battery is about 300 ~ 500 times. The cycle life of VRLA battery is 1000 ~ 1200 times. One of the factors affecting the cycle life is the performance of the manufacturer's products and the other is the quality of maintenance work. The service life of stationary lead-acid battery can also be measured by floating charge life (years). The floating charge life of VRLA battery is more than 10 years.

04 Storage performance

During the storage of the battery, the impurities, such as positive metal ions, can form a micro cell with the negative active materials, resulting in the dissolution of negative metal and the evolution of hydrogen.

If the standard electrode potential of impurities dissolved in the solution and from the positive grid is between the positive and negative standard electrode potentials, it will be oxidized by the positive electrode and reduced by the negative electrode. Therefore, the existence of harmful impurities, so that the positive and negative active materials are gradually consumed, resulting in the loss of battery capacity, this phenomenon is called self discharge.

05 Battery electromotive force, open circuit voltage, working voltage

The product of electromotive force and unit electric quantity indicates the maximum electric power that can be done by unit electric quantity.

The working voltage of the battery refers to the terminal voltage at which the battery has current flowing (closed circuit). The working voltage at the beginning of battery discharge is called initial voltage. After the battery is connected to the load, the working voltage of the battery is lower than the open-circuit voltage due to ohmic resistance and polarization overpotential.

06 Internal resistance

Battery internal resistance includes ohmic internal resistance and polarization internal resistance, and polarization internal resistance includes electrochemical polarization and concentration polarization. The existence of internal resistance makes the terminal voltage of the battery lower than the electromotive force of cells and open-circuit voltage when discharging, and higher than the electromotive force and open-circuit voltage when charging. The internal resistance of the battery is not constant, and it changes with time during charging and discharging. Because the composition of active substances, electrolyte concentration and temperature are constantly changing.