Negative Plate Drying Machines: Secrets to Perfect Drying

2025-11-20 15:22Contents

1. What Exactly Is a Negative Plate Drying Machine?

2. Why Proper Drying Is a Make-or-Break Step

3. The Most Common Drying Problems You'll Run Into

4. How Modern Plate Drying Machines Fix These Issues

5. Must-Have Features When Choosing a Plate Drying Machine

6. Different Drying Technologies Explained Simply

7. How the Right Dryer Affects Your Energy Bill and Output

8. Simple Maintenance Tips to Keep It Running Smoothly

9. Safety Features You Should Never Skip

10. A Reliable Negative Plate Drying Machine Worth Checking Out

What Exactly Is a Negative Plate Drying Machine?

A negative plate drying machine is specialized equipment used in lead-acid battery production lines. After the negative plates are pasted and cured, they still hold a lot of moisture. This machine removes that water quickly and evenly so the plates can move on to the next steps—flash drying, envelope stacking, or assembly—without cracking, warping, or oxidizing.

Think of it as the final "hair dryer" for freshly made negative plates, but built for industrial speed and consistency.

Why Proper Drying Is a Make-or-Break Step

If plates go forward too wet, you get:

• Active material falling off during handling

• Poor formation efficiency later

• Higher internal resistance in the finished battery

• Shorter cycle life for the end user

If they're dried too aggressively, the plates crack or the lead grid corrodes before you even assemble the battery. Getting the moisture level just right—usually below 0.5%—is what separates good batteries from scrap.

The Most Common Drying Problems You'll Run Into

Most factory managers complain about the same things:

• Uneven drying—edges dry while the center stays wet

• Plates sticking to conveyor belts

• Dust and paste particles flying everywhere

• Too much energy used for the amount of plates processed

• Long drying times that bottleneck the whole line

These issues waste material, slow production, and drive up costs fast.

How Modern Plate Drying Machines Fix These Issues

Today's negative plate drying machines use multi-zone hot air circulation, infrared pre-heating, and precise humidity control to dry plates gently and uniformly. Some models add vacuum assistance or radio-frequency drying to cut time without raising temperature too high. The result: plates come out flat, clean, and ready for the next process in under 10 minutes instead of hours.

Must-Have Features When Choosing a Plate Drying Machine

Look for these when you compare machines:

• Multi-layer conveyor – dries more plates per hour in the same footprint

• Adjustable air speed and temperature per zone

• Automatic moisture detection and feedback control

• Easy-clean stainless steel interior

• PTFE or silicone non-stick belts

• Heat recovery system to cut energy use

• Touch-screen PLC with recipe storage

A machine missing even one or two of these will cost you money every shift.

Different Drying Technologies Explained Simply

Hot-air tunnel – cheapest and most common, good for standard automotive plates

Infrared + hot air combo – faster, gentler on thin plates

Radio frequency (RF) – expensive but dries thick industrial plates in minutes

Vacuum drying – rare, used only for ultra-high-performance plates

For 90% of lead-acid factories, a well-designed hot-air negative plate drying machine with infrared boost gives the best balance of speed, quality, and running cost.

How the Right Dryer Affects Your Energy Bill and Output

Old single-pass dryers can eat 300–500 kWh per ton of plates. New energy-efficient models with heat exchangers and insulation drop that to 120–180 kWh/ton. On a line making 5 tons of plates per day, the savings pay for the new machine in 12–18 months. After that, it's pure profit and more plates out the door.

Simple Maintenance Tips to Keep It Running Smoothly

Every week: clean filters and check belt tension

Every month: inspect heaters and lubricate bearings

Every six months: calibrate temperature and humidity sensors

Do these small jobs and your plate drying machine will run trouble-free for years.

Safety Features You Should Never Skip

Make sure the machine has:

• Emergency stop buttons on all sides

• Over-temperature alarms and auto shutdown

• Explosion-proof fans (lead dust is flammable)

• Door interlocks

Cheap machines without these put your workers and factory at risk.

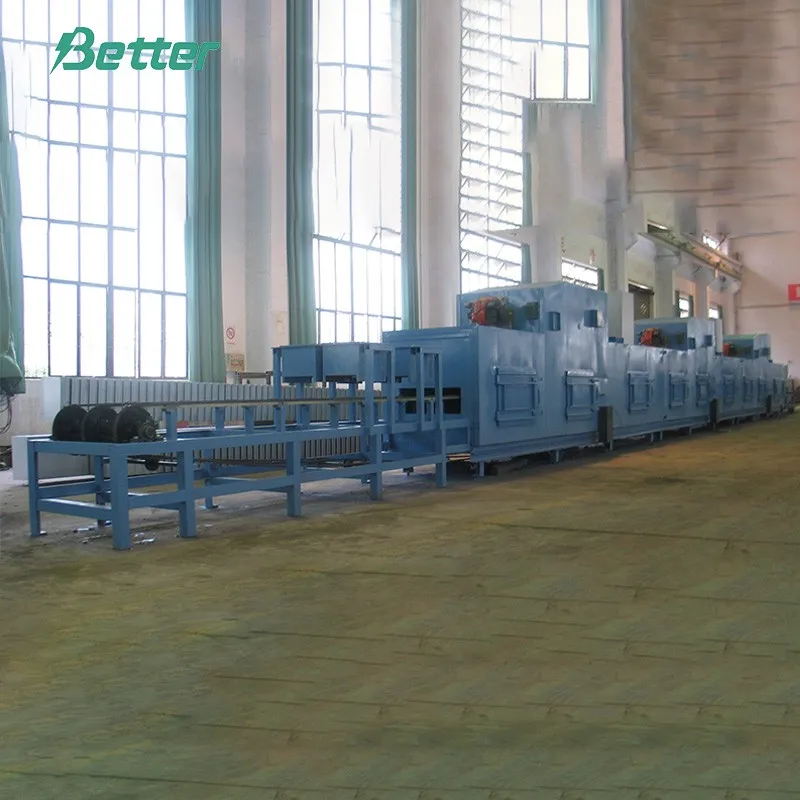

A Reliable Negative Plate Drying Machine Worth Checking Out

If you're looking for a proven, energy-efficient solution that checks all the boxes above, take a look at Better Tech Group's negative plate drying machine. It uses multi-zone hot air + infrared, automatic moisture control, and heat recovery to deliver perfectly dried negative plates with low energy consumption and almost zero maintenance headaches.

You can see the full technical specs and request a quotation here.