Automatic Acid Filling and Acid Level Adjustment Machine

Automatic Acid Filling and Acid Level Adjustment Machine used for automotive battery (12V40~200AH) acid filling and acid suction after battery formation.

Features : numerical control quantification, measuring cylinder is automatically adjusted through lifting height adjustment by the rotary encoder, the machine adopts negative pressure type acid absorption mode.

- Information

- Video

Application: For battery weighing and acid level adjustment after acid filling.

Operation: The battery is automatically input into the feed weighing system. After the weighing data is collected, the battery is automatically conveyed to the acid refill and acid leveling station.

Features: The machine has two working stations, i.e. acid refill and acid leveling station + weighing station (or customized). The method of acid refill is numerically controlled and the machine adopts negative pressure for level adjustment. The circulation of quantification, acid refill, vacuum and acid refill can be set. The loading weighing system has the functions of data collection, display, storage and reading.

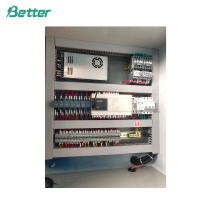

Main Configuration: 316L stainless steel frame, PP plastic acid proof belt, Mitsubishi PLC, Mitsubishi HMI, customized weighing system, AirTAC pneumatic components, Schneider low-voltage electrical appliances.

Acid Refill Volume: 50-1000ml/nozzle

Acid Filling Speed: 1000ml/min/ nozzle

Acid Filling Accuracy: 1000ml/min/ nozzle

Production Capacity: 1000pcs /8 hours

Air Source: 0.1m³/min, 0.6mpa;

Power Supply: AC380±20V, 50HZ, 2KW;

Dimension (L×W×H): 2600×950×2000mm

- The first vacuum can be set as 200~400mbar (0.02-0.04Mpa), and the second vacuum can be set as 400-600mbar (0.04-0.06Mpa).

Working Process: quantification, acid refill, vacuum, acid refill, vacuum (circulation)

The weighing system data and the acid filling machine share one PLC;

Weighing system data can be collected and recorded in PLC;